AI Produced Design for Additive Manufacturing

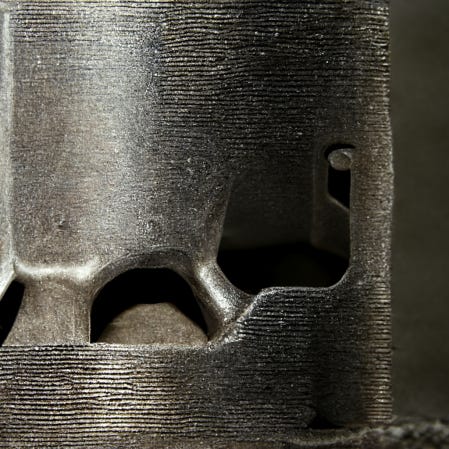

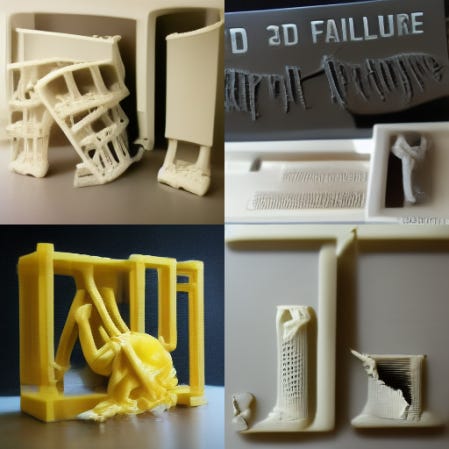

A gallery of results of AI produced DfAM

There have been a number of articles and academic papers about AI driven design for additive manufacturing and there has been some progress on build preparation and optimization side but has there actually been any objects designed using AI alone?

Sometimes journalists are either confused or misled when they describe generative design and topology optimization as using AI which is not quite the case.

Topology optimization (which can be a subset of generative design) uses simulation to optimize a geometry based on load path through a given design space based on forces, constraints and maybe material.

Generative design typically uses a set of rules to define a geometry or geometries based on simulation or other data, the results can then be ranked and compared across multiple metrics but I have yet to see an AI trained on real world data in a commercial software product.

Training an AI for design on simulation/synthetic data may be an option to speed up the simulation process, but without real world data the results it is a resonant feedback loop based on simplifications and assumptions.

There has been research using controlled natural language as an input for designing objects by specifying criteria and constraints but it seems we are many years away from this in a commercial product.

Perhaps we can have a sneak peek what that may look like today though…

After seeing Onur Yüce Gün’s (Expert and Tireless Critic of Computational Design) recent posts on LinkedIn questioning the sudden tidal wave of AI images being produced with little or no meaning or value I thought, oh, I can do that.

So, I signed up to a trial of MidJourney taking a cue from the natural language research by Autodesk and Onur’s provocation and in the span of about 30 minutes may have become the first person to actually design for AM using AI.

(prove me wrong in the comments)

And last but not least…