Citrine Platform & Informatics & AI for Materials Development

CDFAM Expert Speaker Series Interview with Justine Trubey

AI and machine learning have been employed for a number of years in material chemistry, though their application in generating 3D geometry is a relatively recent development.

Citrine Informatics is at the forefront of this industry, providing a software platform that harnesses AI and robust data management infrastructure. This has empowered some of the largest materials companies worldwide to enhance their material development processes, resulting in superior performance and greater sustainability of materials, chemicals, and products.

At CDFAM, Chief Operating Officer of Citrine Informatics, Justine Trubey, will delve into how Citrine's AI-driven platform enables large corporations to utilize their own data to expedite their material development process. The aim is to contribute to a more sustainable future through improved efficiency and innovation.

Following is an excerpt from out conversation, the full interview can be found on the CDFAM 23 event site.

Could you begin by providing a brief overview of Citrine Informatics, its mission in the materials science and AI industry, and some examples of the types of applications it has been used for?

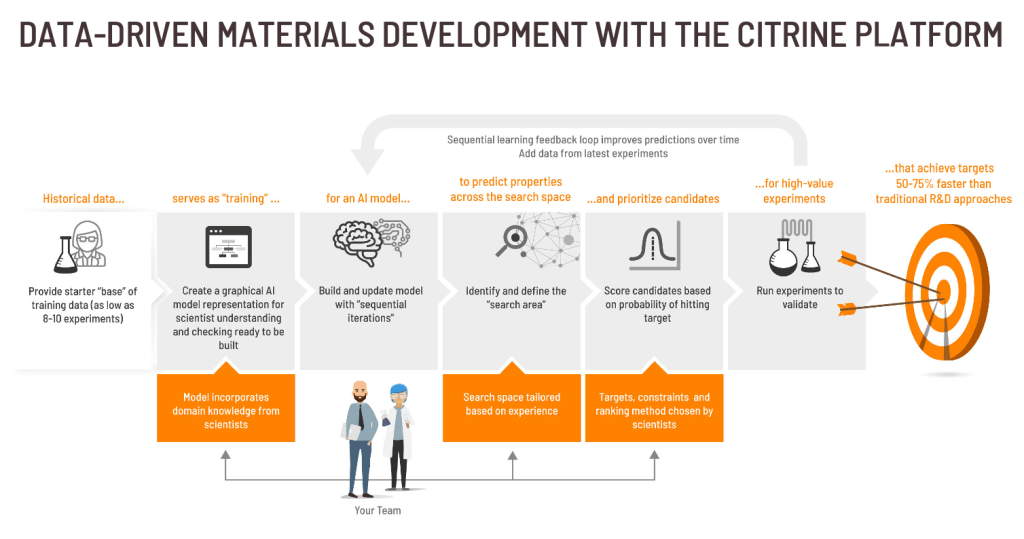

The Citrine Platform, a SAAS product, combines domain-specific AI algorithms and smart data management infrastructure to establish structure-property relationships of materials and allows for the storage, retrieval, and interpretation of these data with high fidelity and interoperability. Additionally, the software offers improved data visualization and tools for integrating domain knowledge.

The Citrine platform allows users to leverage AI and MI without needing to develop their own MI infrastructure in-house. It can help users meet sustainability goals through design, significantly accelerate product development, and provide chemicals and materials companies stronger flexibility and adaptivity to handle changing market demands due to megatrends, short-term events, and customer preferences.

The Citrine Platform (CP) accelerates the pace of innovation across a wide range of industries, including specialty chemicals, coatings, batteries, and CPG.

We have a deep sustainability mission to enable more performant and sustainable materials development faster.

Can you give some examples of the types of applications the Citrine Platform and AI-driven Materials Informatics has been used for?

Here are just a few, ranging from the mundane to the sublime (anonymized):

Taking PFAS out of an company’s entire supply chain

Developing a lighter metal to improve energy efficiency in airplane engines

Creating shampoo that doesn’t separate on the shelf

Choosing the most performant solvent blend (with complex ingredients and processing parameters) from more than 850 million options

Optimizing organic semiconductors for IOT applications

Making a cheaper and better non-slip coating for tools

Can you provide us with an overview of the key topics and themes that you plan to cover in your upcoming presentation at CDFAM, “Informatics and AI for Materials Development”?

How our customers perceive materials in their strategies, the problems it solves and how that all changes with AI and data driven methodologies

What is Materials Informatics and Sequential Learning, and why digitize product development?

Accelerated Product Development

Data Driven R&D Portfolio

Enterprise Knowledge Management

What does “better ma

Using data in the product development and mfg space

Competitive advantage

Manufacturing efficiencies

Sustainability and why hasn’t every company done this yet?: Obstacles

The Grey Areas

Some cool examples

Could you elaborate on how Citrine’s AI-driven approach can enhance the agility of materials exploration and development in order to respond effectively to sudden changes in supply chain dynamics or regulatory environments?

Citrine came to a virtual standstill during the first few months of Covid. No one went to the lab, ingredients were not being mined or made, and lines were shut down. There were epic supply chain disruptions, massive cuts in manufacturing capacity, and unprecedented, unpredictable changes in demand.

Most manufacturers struggled to get raw materials; but once the first kick of dust cleared, they needed to go into overdrive on production. With China (and other logistics solutions) almost completely out of commission, the raw materials that manufacturers always used to make chemicals and products were no longer available, and they needed to find new ones.

(Thankfully) Regulatory pressures are becoming more stringent, every day brings a declaration about bans or thresholds in manufacturing. Companies need different formulations, new suppliers, and different processes to make and throw away new products, with optimized outcomes.

To change materials for manufacturing, you need to test test and test, and the trillions of possibilities require more than just the human brain to get the job done.

Finally, what do you hope to take away from your interactions with other experts at CDFAM exploring AI in their work but may not actually be doing so yet. Do you have any words of caution or advice for them?

The way we consider design and manufacturing is entirely upended by digitization. It is cross-functional, global, and affects every single aspect of our industry and human development.

AI itself is a juggernaut–one of the most powerful developments in our lifetimes. I am excited to hear what my colleagues are doing, learn about the grey areas between good and evil, and where we are headed.

Read the full interview, and to hear more more from Justine and other AI and manufacturing expert’s fight against evil, register to attend CDFAM June 14-15 in NYC to ensure you are also on the right side of history.