Computational Advances in Footwear Design at CDFAM Amsterdam 2025

At the cutting edge of footwear design and manufacture.

The 2025 program for CDFAM Amsterdam includes a number of presentations focused on footwear, highlighting how computational methods are being integrated into design, engineering, and manufacturing workflows. Presentations from On, VivoBiome, and Framas each explore different aspects of how algorithmic approaches, automation, and additive manufacturing are reshaping the footwear industry.

Upcoming Presentations at CDFAM Amsterdam

MAIA ZHELIAZKOVA – ON

LightSpray™: A New High Performance Upper Technology Crafted by a Revolutionary Single-Step Manufacturing Process

Maia Zheliazkova presents On’s LightSpray™ process: a fully automated method for producing shoe uppers using a robotic spray system. The presentation focuses on how computational design and robotic programming are used to engineer ultralight, one-piece uppers in a single manufacturing step, eliminating traditional pattern making, reducing waste, and enabling rapid iteration.

RENÉ MEDEL – FRAMAS

Injecting AM into Shoes

René Medel, Senior Digital Creation Engineer at Framas, presents how additive manufacturing is being incorporated into traditional mold-making for footwear. With experience in both digital tools and production, Medel outlines how computational design and AM can support more flexible, iterative development processes while remaining compatible with high-volume manufacturing.

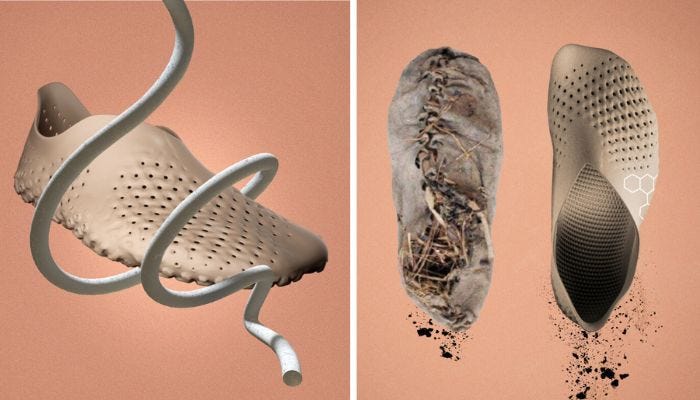

PETER DAVIS – VIVOBIOME

Native Machine Code for Mass Customisation of Products

VivoBiome outlines a workflow built around Signed Distance Fields (SDFs), where customer-specific data is translated directly into native machine code. The approach bypasses conventional CAD and slicing, automating the path from scan to production-ready geometry. The system integrates 3D scanning, algorithmic modeling, and robotic manufacturing to enable scalable mass customization of footwear.

SEE THE FULL PROGRAM FOR CDFAM AMSTERDAM

Previous Presentation on Footwear at CDFAM

While CDFAM Amsterdam 2025 presents a concentrated group of sessions on computational design in footwear, the topic has been part of the broader conversation at CDFAM since its inception.

At the first CDFAM NYC, several talks explored computational and automated processes relevant to footwear. Natalie Alima (BioLab + Adidas) presented at the very experimental end of the spectrum with Interspecies Forms, a study of mycelial growth and robotic feedback systems, addressing how biological computation can influence performance-driven design. Moving on to explore how this approach might find it’s way into the most cutting edge streetwear brands on the planet.

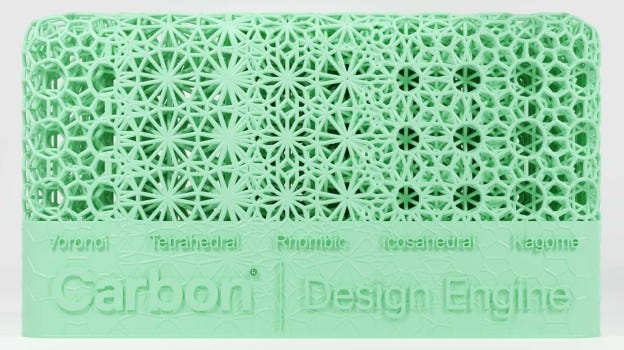

In the same session, Hardik Kabaria (Carbon) discussed inverse design of metamaterials using machine learning to optimize the performance of FutureCraft midsoles, also for Adidas during his presentation DEFINING PERFORMANCE NOT JUST GEOMETRY WITH SOFTWARE, PROCESS + MATERIAL SCIENCE.

Ronnie Parsons (Mode Lab) discussed some of the work they have explored with Nike on the intersection of software, material science, and manufacturing—setting the stage for a design process that defines performance outcomes, not just geometry.

Subsequent CDFAM events in Berlin featured more targeted applications. Jesus Marini Parissi (MoonrabbitX) presented on Computational Processes for Adaptive Biomechanics, focusing on generative tooling for footwear tailored to individual biomechanical conditions. René Medel (Framas) contributed multiple times, most recently presenting on Generative DfAM in the Footwear Industry, where he examined the role of algorithmic design across physical processes including foaming and injection molding.

Ruiqi Chen and Andrew Sink (Carbon) addressed computational design at scale in their presentation The Road to One Million Custom Parts Per Month. While not limited to footwear, the talk revealed the infrastructure required to support product-specific customization through computational design and additive manufacturing.

Why Computational Footwear?

Footwear presents a compelling design and manufacturing challenge where computational methods can offer immediate value. Every model must balance structural performance, comfort, and aesthetics—while accommodating dozens of sizes and foot shapes. Traditional workflows often treat each size as a separate manual task, limiting design iteration and increasing lead times.

Computational design allows for parametric control of geometry, enabling scalable modification of structures across size ranges while maintaining performance criteria. This is particularly relevant in areas like sole cushioning, where lattice structures can be tuned per size and even per user.

Combined with additive manufacturing or flexible molding processes, these models can be directly linked to production without manual rework.

The presentations at CDFAM Amsterdam 2025 highlight how computational approaches are being used not just to design shoes, but to rethink the entire pipeline—from scan to print, from robot to foot.

Expanding the Context

The application of computational design in footwear doesn’t exist in isolation. Onur Yüce Gün, from New Balance, has twice addressed CDFAM audiences with a broader lens on how computational processes are reshaping the act of designing itself.

In his 2023 NYC opening keynote, Design Computation Human, he explored the relationship between design and machine intelligence through the lens of footwear, architecture, and art.

His Berlin 2024 closing keynote, Shape of Generative AI, expanded this further—urging designers and engineers to actively develop strategies for working with emerging AI systems rather than reacting to them passively.

His message echoes across the footwear-focused presentations at CDFAM: computational methods are not just tools for form generation or automation, but frameworks for new design reasoning. From performance optimization to scalable customization, the footwear industry is revealing how these approaches can be implemented with precision—and at scale.

Software Companies Supporting Computational Footwear Design

Many of the innovations presented at CDFAM—past and present—rely on the capabilities of specific software platforms developed for algorithmic modeling, simulation, and production automation. These tools enable designers and engineers to work parametrically across size ranges, simulate performance outcomes, and link seamlessly with digital manufacturing systems.

NTOP

nTop’s implicit modeling engine is widely used in aerospace, medical, and industrial design, but its field-driven design tools and robust handling of complex geometry are directly applicable to footwear. Midsoles, cushioning systems, and performance-tuned lattices are increasingly being developed using nTop workflows, with built-in support for multi-physics simulation and design iteration across size ranges.

CARBON

Carbon’s software stack—including Design Engine—has been central to the development of computational midsoles for brands like Adidas. Their tools allow designers to link lattice density, elasticity, and energy return directly to performance criteria, using dual-cure materials optimized for additive production at scale.

SHAPEDIVER

Used by VivoBiome as part of their mass customization pipeline, ShapeDiver connects parametric Grasshopper definitions to the cloud, allowing customers or designers to adjust parameters and instantly visualize results in a browser. This has been key for user-facing customization tools where individual foot geometry needs to be mapped to manufacturable output.

SPHERENE

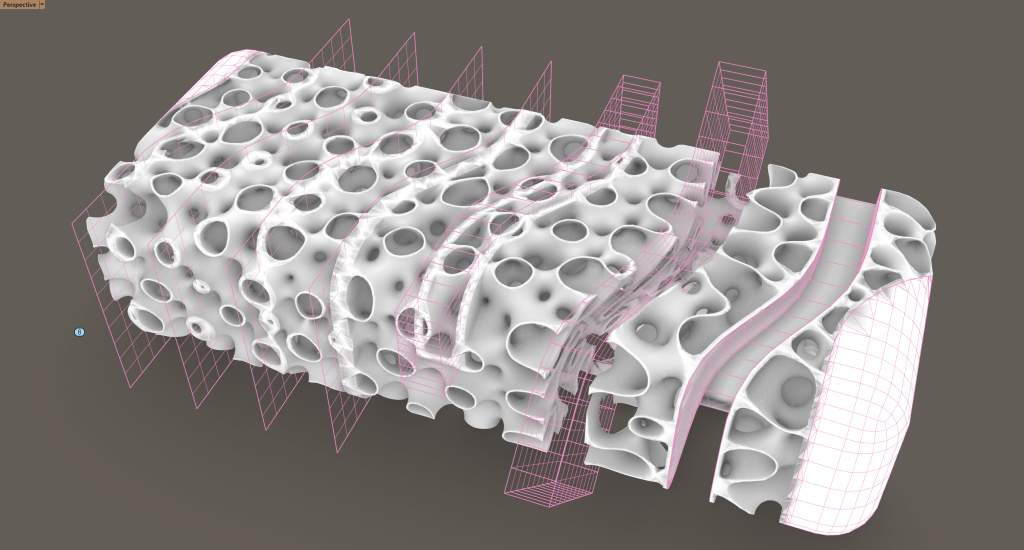

Spherene’s Adaptive Density Minimal Surface (ADMS) technology enables the generation of highly optimized lattice and shell structures using implicit modeling. Designed to minimize material usage while maintaining strength and performance, ADMS Spherene® is particularly relevant to applications like footwear, where weight, flexibility, and localized performance all matter. Their software integrates with both Grasshopper (for parametric control) and Fusion 360 (for CAD-CAM workflows), making it accessible to both experimental designers and engineering teams. Spherene’s tools are used to rapidly generate structures ready for additive manufacturing, helping bridge the gap between complex geometry and production feasibility.

HYPERGANIC

Hyperganic’s design platform, HyDesign, enables engineers to generate complex, performance-driven geometries through fully programmable workflows. Rather than modeling shape manually, users define the logic and constraints, and HyDesign creates optimized structures—ideal for applications requiring high customization and functional integration, such as footwear components. With the ability to encode material behavior, structural requirements, and manufacturing rules into code, Hyperganic allows for scalable, automated design pipelines that can produce thousands of unique parts with minimal human input. Their approach is especially relevant as footwear brands explore generative tooling, advanced midsole structures, and robotic manufacturing processes.

ALTAIR

Altair’s simulation and generative design platforms—including Inspire and OptiStruct—have long been used for structural optimization. As additive manufacturing has expanded in footwear, Altair’s tools for topology optimization, lattice generation, and multi-objective simulation are increasingly relevant, especially in the early-phase exploration of performance structures like midsoles and support systems.

RHINO + GRASSHOPPER

Still the core of many computational workflows, Rhino and Grasshopper remain foundational in experimental and production-ready applications. Framas, MoonrabbitX, and many others rely on this ecosystem for logic-based design, integration with external data (like foot scans), and the creation of responsive geometry for downstream processes like AM, injection molding, or robotic manufacturing. Often using user designed plugins, like Crystallon for Rhino for lattice structures and Intact Solutions for simulation.

Learn More at CDFAM Amsterdam

From generative automation to mass customization, computational design is no longer a future vision for footwear—it’s here, and it’s evolving rapidly.

CDFAM Amsterdam 2025 brings together the engineers, designers, and software developers leading this transformation, offering a rare opportunity to see behind the scenes of cutting-edge projects and tools shaping the next generation of product development.

Whether you’re working in footwear, industrial design, or computational manufacturing more broadly, this is your chance to engage directly with those driving innovation—ask questions, share approaches, and build connections across industries. With presentations from leading brands, emerging startups, and the software platforms powering them all, CDFAM offers both strategic insight and practical takeaways.

If you’re looking to understand where computational design is headed—and how to apply it to your own work—Register to attend CDFAM Amsterdam.