The Importance of DfAM Education

More than just Machines, Materials and Software, is the need for People with DfAM Expertise.

There is a common understanding that there are three pillars of additive manufacturing: Machines, Materials and Software. That all three of these aspects need to mature together to advance additive manufacturing.

One aspect that is not getting quite as much attention is the need for people who understand how, where and when to apply the technology at the same rate as the technology advances.

Universities and research organizations around the world are focusing heavily on the manufacturing processes and materials themselves, which continually advances the state of the art in these areas. This research and development creates a strong foundation of knowledge, along with thousands of engineers with a deep understanding of these materials and processes, ready to join, or inform the workforce.

Less attention and research has been applied to design for additive manufacturing, and education the engineers on the benefits of AM, not just the material properties and constraints.

A rudimentary google scholar query turns up 1,830 articles mentioning ‘DfAM Additive Manufacturing’ between 2011 and 2021 where ‘Additive Manufacturing’ returns 676,000 results for the same period.

And yes, there are articles that mention designing a lattice structure and reviewing their performance as a test specimen, articles about design using topology optimization for mechanical and thermal performance as well as a plethora of research and acquired knowledge around design for additive manufacturability, overhang constraints, aspect ratios, wall thicknesses and alike.

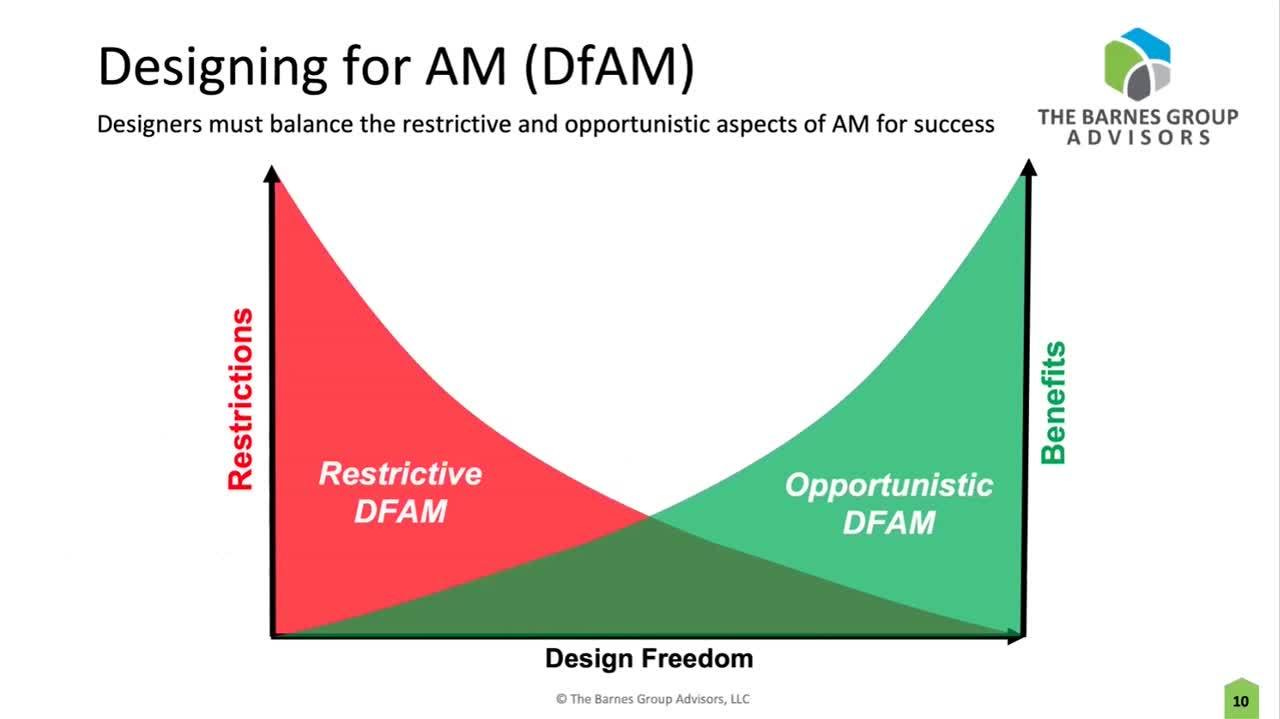

There is also research into the efficacy of when DfAM concepts are introduced to an engineer/student and what they are able to synthesize and adopt with more success. There is evidence that the earlier in a learning cycle the more the learner is capable of adopting more creative, opportunistic and expansive design solution but that design guidelines, restrictions and constraints are more easily learnt and applied.

Whilst ‘design guidelines’ are relatively easy to understand and implement for a given technology, rethinking the design process and business models of additive manufacturing require deeper analysis and understanding that can be very nuanced from one manufacturing process to another, and can take time to synthesize and apply.

True design for additive manufacturing is more than just design for manufacturability, it also encompasses rethinking they way we approach design and engineering to achieve multiple requirements simultaneously, be they mechanical, thermal, hydraulic, electromagnetic, aesthetic, assembly, inspection environmental and importantly, the business case.

The benefits are not always as simple as lighter, faster or cheaper to manufacture, but must also consider the entire life and performance of the manufactured object.

This understanding is often developed through time consuming and expensive experimentation to gain experience, but we are now at the stage that this experience from both academic researchers and experts from the field is being synthesized into coursework in educational institutions around the world to arm the emerging generation of engineers that must include DfAM skills and understanding.

Following is a list that is in no way comprehensive, of some institutions and companies that offer DfAM coursework, along with institutions with dedicated research into design for additive manufacturing.

Many of these courses also have elements of actually running machines, material development, post processing and GD&T, and there are many other courses focus purely on the latter aspects, but the focus here is on those that have a significant DfAM component.

Penn State offers an online Masters of Additive Manufacturing and Design as well as a Graduate Certificate in Additive Manufacturing and Design.

MIT offers a 12 week course of Additive Manufacturing for Innovative Design and Production and focuses on the fundamentals, applications, and implications of printing for design and manufacturing.

Imperial College London offers DfAM coursework and research.

Carnegie Mellon University has both a Master of Science in Additive Manufacturing as well as an Undergraduate Minor in Additive Manufacturing.

Ohio State offers an intro to AM with a DfAM component.

RMIT has a long history in Design for AM

Monash University offers a DfAM course

Virgina Tech haș their Dreams Lab with an AM focus.

Stanford offers their ME127 Design for Additive Manufacturing course.

John Hopkins also has a DfAM course that has a metal AM prerequisite.

Purdue has a number of online DfAM courses

University of Nottingham has a full year AM course.

UT of Austin has a number of AM + DfAM initiatives including hosting the Solid Freeform Fabrication Symposium which is one of the most impressive AM research events of the year.

Arizona State has a graduate course in DfAM

TU Darmstadt offers research areas in DfAM

TMG Munich runs a 4 week DfAM course with 1 day in person per week.

Calhoun Community College has a short term certificate that includes DfAM

University of Cambridge and Loughborough University have a joint DfAM initiative along with their own dedicated AM research groups including my favorite ever PhD subject Designing Extremely Complex Geometries

Fulton runs a DfAM course every 2 years, maybe?

Barnes Global Advisors offer a number AM training courses including DfAM and Advanced DfAM

ASME has a number of Design for Additive Manufacturing

Gen3D has a free online DfAM Course

Wohlers & ASTM offer occasional DfAM courses and a separate DfAM certificate

HP has MJF specific course work

EOS has a metal specific DfAM course as well as a polymer DfAM course

It is great we are seeing more and more opportunities for people to get up to speed and learn about DfAM but we need to ensure we do not stop at design guidelines and constraints but continue to encourage the exploration of opportunities and benefits.

Disclaimer: I am currently working as a teaching assistant on the MIT Additive Manufacturing for Innovative Design and Production course. I am honestly really impressed by the breadth and depth of the content that is covered in the course and think it is an amazing resource for anyone getting started in AM and of value for anyone who wants to broaden their understanding of additive manufacturing in general.