DfAM Q&A with Marco Preziosa of Add+it

The 'Additive Mindset' and Design as the Language of AM Physics

Marco Preziosa is the founder and CEO of Additive Italia Srl, also known as Add+it, an Italian based consultancy specializing in design for additive manufacturing. Their services include consulting on where and when AM can solve both engineering and business problems, DfAM to solve specific problems with AM, as well as training clients on process, design tools and technologies around AM.

In this Q&A, Marco poetically explains his philosophy of the business of DfAM, where and how the value of AM can be maximized with careful consideration of opportunities and constraints, and how he and his team transfer their expertise and enthusiasm to their clients.

Q.

What led you to form Add+It Tech, who are the team members and what is their background.

A.

I grew up in my family business sheet metal workshop and was fascinated with new tech, machinery and process automation. This background provided a sort of natural awareness of the organic process which brings customers’ needs into valuable ideas then to be digested through ever changing and adapting industrial processes as to be turned into problem-solving products.

I’ve always been keeping an eye on “3d printing” and when the tech was eventually ripening to become a true industrial process, I saw both risk and opportunity of the widespread inadequate mindset in adopting this as a mere substitution of traditional machinery with “something new and fancy” or a scale-up of “rapid prototyping”.

The best part of the opportunity this manufacturing paradigm change is providing is at stake, we risk to get it lost in translation because of stubbornness, manufacturers are usually raised in the “best practice” of cautious incremental evolutionary approach to improvement of products and process.

It was 2017, and I thought my understanding of the magnitude of change and proper approach could be of use to many, my bread-and-butter sheet-metal isn’t exciting that much so I decided to spice up my work diet.

The other 50% of the company is my wife Simonetta Oberti. Since her M.sc graduation in mechanical engineering she has been working in different industrial manufacturing companies ranging from the engineering of HVAC conditioners in Carrier (United Technologies) to process management in various branches of the heavy steel tubing for O&G company Tenaris. Then she joined me in the sheet-metal business and her expertise in industrial process management now ranges from big corps, heavy industry to SMBs

Our team is gradually growing, in June 2019 Gianluigi Rossi joined us, he’s young and passionate about everything related to 3D printing. Graduated in 2019 in Materials and Nanotechnology Engineering at the Politecnico di Milano, he attended the first European AM course for space and aerospace applications with his master's thesis: ‘Development of new high-strength aluminum alloys for SLM in collaboration with the European Space Agency (ESA)’. He attended the DfAM course on the Altair suite in 2019 at Weisoft and the Desktop Metal user training at the headquarters in Boston. He is Application & Process Engineer at Additive Italia, he is responsible for managing the DfAM, the Lab and supervising the research and development operations and networking activities.

We are hiring now, a junior Application Engineer is needed to help Gianluigi and we’ve just hired a junior Process Engineer for the Lab.

Q.

What are some common themes you are seeing emerging from clients, what is driving adoption of additive manufacturing and the realization that design is key to success.

A.

Generally speaking the AM adoption drivers in industrial application is definitely “customization”.

There is a huge “value reservoir” in going to customers with fine tuned solutions which make so much sense to them in terms of efficiency, availability, and so on just because nobody even thought a design was “industrially” achievable. This goes from a “one off” on an industrial machinery to “just” a few hundred thousands in the automotive (which usually talks about millions of same parts).

Then you have “mere” design related objects such as in fashion applications (and cosmetics, luxury packaging, and so on) and again you have a great variation in numbers, materials and requirements (esp. with finishing) where design “fanciness” is a different expression of the same language.

Let's say it's theater in industry and poetry in fashion.

Q.

What are common misunderstandings clients have of DfAM and additive manufacturing in general on initial engagement?

A.

As for DfAM the main misunderstanding is thinking of it as just a matter of a differently spiced CAD: as AM is said to overcome traditional manufacturing constraints and enabling free-form, somehow somebody happen to think DfAM is designing whatever a supposed “DfAM CAD” is able to render. I'd say designers clueless about AM process are not making DfAM but industrial digital art, at best.

About additive manufacturing the major misunderstanding is thinking the first thing (alas sometimes the whole thing) is “the printer” instead of addressing what’s the problem to be solved and why AM is a good solution i.e. identifying value to customers as a target (which AM and proper DfAM are so good at seizing)

Q.

What are some issues you see arise that block the adoption of additive manufacturing as a solution.

A.

Talking about industry I see many hurdles on the way.

One major problem is too much cautious conservatism in reconsidering the whole value chain at stake with this disruptive (ok enough with this D word) transformation of the process. This reflects the usual way of thinking, OODA (observe-orient-decide-act) loop in small segmented bits of the process and evolutionary iterations where innovation often happens to be just replacement of an old machinery with a newer and better one performing in same task. So far so good until you raise your eyes from your desk and there’s an elephant in the room: competitors had taken the risk and having a different idea of innovation now provide better value which your customers happen to appreciate.

In few words, inappropriate risk/opportunity assessment.

Another problem is budget allocation. I don’t mean just money, but more significantly, time of brilliant minds devoted to understand how and in which way this opportunity of creating a digital asset which embodies the company knowledge to provide value to customers can shift business and escalate to a different, global and profitable playground, a reset of competitiveness, a different championship. This is the high prize, but if companies don’t get it they will hardly embrace the costly learning curve even if they have the finance, the time, the smart people and the business opportunity, they will get eventually stomped by a big white AM elephant in the room.

This also tells about another problem which is business structure, SMEs are in many cases already under pressure in so many aspects (finance, margins, staffing and competence shortage to tell a few) that such an effort is a bit too much for them. SMEs are generally quicker and smarter than big corps, are used to sharp changes and more likely have the open-minded approach to the whole AM tale, they get the picture, but can’t do much on their own in face of such a magnitude of change. A new form of coopetition is needed, a sort of federate process. Work in progress, on this matter also, at Add+it.

Q.

What are some of your favorite projects you can talk about?

A.

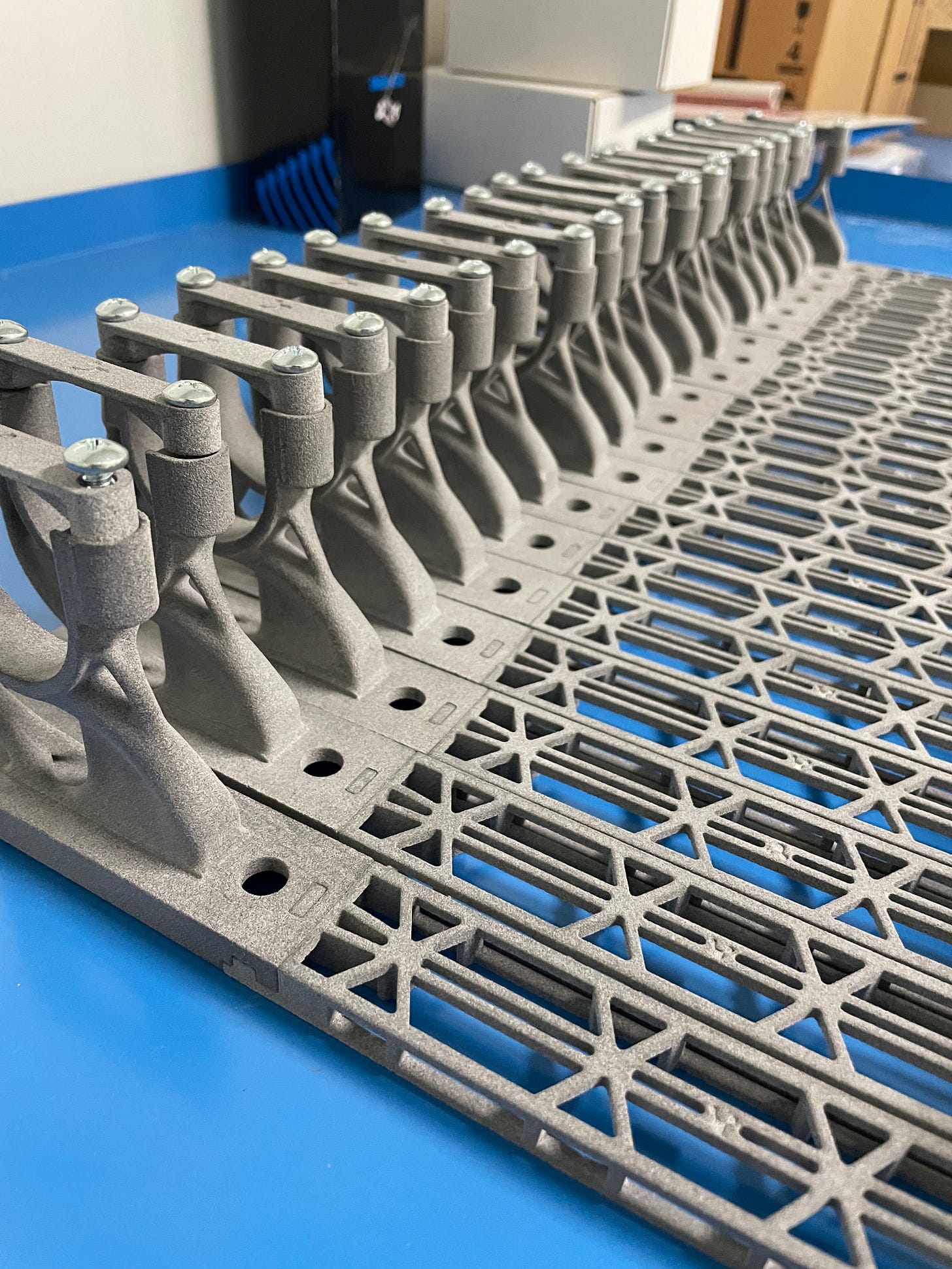

We have been involved with various projects and applications, using metals and polymers, ranging from industrial automation, fashion and prosthetics to high volume industrial machinery components.

As I mentioned, imprinting plays a significant role in shaping the mindset of a manufacturing guy, due to nearly my half-a-century acquaintance with a manufacturing workshop playground when it comes to AM projects my favorites are those related to industrial applications which, easy guess, happen to be under strict NDA rule.

But I can tell you that the most intriguing aspect of all those projects is exactly how we gradually build up confidence in our customers that AM truly is a great way to provide valuable usefulness the more you are open to profit the wide spectrum of opportunities arising from a wise, focused, tailored and target driven combination of the usual magic ingredients to be stirred in the AM pot: simulation driven design, materials, AM technologies and finishing.

Then comes the enlightenment: we have to build a proper workflow, a conformal process from the ground up, from value engineering to physical product.

Q.

How does your design consultancy work, can you walk us through a ‘typical’ consulting process, and what is your business model?

A.

There’s not a standard pattern to date, but surely the same initial point: We listen.

We just sit down and listen to what in our customer’s problem makes AM an opportunity to bring up value. There are still a lot of misconceptions about what AM is, and what is not (cheap and dirty for instance, a magic wand, printers like push button machines turning files into gold), so not every problem is likely to get the right answer from AM. I tend to have a frankly disruptive approach on all the hype surrounding the AM world as I know my colleagues handling the industrial manufacturing business.

I’m just uncomfortable with fragile expectations as they are when it comes to industrial processes not delivering as promised.

If problems and opportunities are consistent with AM toolbox we depict what AM can mean in terms of technological paradigm and just ask to which extent they are willing to engage time, people an money to understand how we can bespoke the adoption process as to define, pursue and meet their goals, set the path and the metrics.

Generally speaking companies are still reluctant to embrace a wide and deep implementation of AM at full scale, and I can fully understand this. When talking of products and brands already on the market, the whole reputation is at stake with such a great change, but still if the whole thing makes sense to all of us we can start familiarizing with a part, a component, an assembly, a tooling, whatever we can find as an object which clearly embodies a “set of problems” representing the high prize the customer sees and make this “business case” a sensitive bunch of pixels of the whole picture.

Once the goal is reached, the confidence baseline is set, we leverage this knowledge into a little bit more ambitious and widespread meaningful exercise. Iterations of the same process provide deeper knowledge and wider focus on the many other value opportunities AM can claim.

The more complex it gets, the higher competences in design and simulation are needed, materials requirements and process performance become demanding and the whole team get excited. You see where my joke of “Addictive Manufacturing” in the company claim comes from.

Q.

Given your company is focused on design for additive manufacturing, how do your clients know that an AM design is the answer to their engineering requirements?

A.

Well, design is not exactly “the” focus. Sure it is one of the biggest part of the equation which I call ‘Additive Mindset’. As we go to industrial applications, design is the process of integrating different tools and knowledge in the shape of the item, eventually providing the solution, incorporating the value.

I would say design is the language of AM physics, you have to conceive the concept of the value and you describe this in your mind with the tools which “design” provides, and you pick them as from your mother tongue vocabulary.

But your design language needs to meet the grammar i.e. constraints of available technologies, materials, productivity and cost. This grammar is constantly evolving, with increasing speed and geometrically growing declinations. This is a great load of knowledge you constantly need to keep hands on.

Q.

Once you identify a problem how do you determine which material and additive manufacturing process to design for, including which software tools?

A.

Basically we break down the project into technical constraints the customer sets as mandatory, targets we need to attain, “nice to have” we can deal with.

You take into account cost expectations (this embodies THE big problem of value consciousness, but this issue deserves an encyclopedia on its own), productivity constraints.

At this point you have naturally come down a selection tree and start dealing with a deep dive into the whole matter, material datasheets and process specs as to simulate then experiment coherent design and materials seeking optimal compromise.

As for software tools we are very happy with our Altair and nTopology licenses as they provide all the robust and friendly capability of dealing the set of physical constraints we need to handle in a simulation driven design iteration, we are growing up our skills in CFD topology optimization too and we will come with some news on that soon, but cannot disclose much at this time.

Q.

Once you have a design/solution that meets the engineering requirements, how do you also ensure the solution meets the business case?

A.

Value, therefore costs, are definitely taken into account at the very early stage of the design process, say they are part of the virtual “design space” just as physics, gravity, E=mc2

Q.

Who are the key stakeholders that must be aligned to approve a design to move to manufacture?

A.

This is a complex question, the answer varies from customer to customer, from project to project. I’d say according to the magnitude of the innovation the project brings to the final customer, the higher the innovation, the more the customer needs to be reassured about risks involved so the higher is the number of stakeholders who need to assess the risk and have their say before green lighting serial production. Not to mention when the field of application has to meet technical regulation such as O&G

Q.

Once a project is complete and a component is in production, what are typical next steps with the client?

A.

Smiles, a coffee, a meeting for a new project, more coffee

Q.

Do you also train a client’s employees on DfAM principles as you go through the process, such as feasibility studies, part/feature/performance consolidation, manufacturing constraints?

A.

Yes, we do provide consultancy and training, our mission is to enable customers to profit the full advantage of AM adoption thus a deep understanding of DfAM in their own engineering and products is mandatory whether they are going to have design and manufacturing as in-house processes or not. We need to talk the same language.

Q.

What most surprises you about clients requests or expectations?

A.

My shiny silver lined hairs are a good excuse not to be surprised by the weirdo coming up from time to time.

Q.

The design tools, additive manufacturing materials and processes are evolving relatively quickly, how do you stay up to date with the latest offerings?

A.

I do not miss a Formnext, read a lot, scan the web, Linkedin, whatever meaningful channel, I stalk each and every manufacturer of AM related hardware and material which can be of interest to my customers requesting evaluations and samples (but only if a real application is in sight, so they are generally more than happy to be of help).

As far as software is concerned, this is a tough matter as the learning curve on ever evolving software is constantly steep. We made our choices we are more than happy with, and continue investing time and effort in leveraging our knowledge.

Of course we keep an eye on novelties and upgrades of other mainstay software, co-operate on dedicated projects, we sponsor graduating and Ph.D thesis enabling candidates to use them so we keep in touch and have first hand glimpse on their capabilities.

Q.

What do you think a designer or engineer needs to understand DfAM potential and constraints?

A.

Training on the software tools is mandatory, you need to know how to tell a simulator to calculate what you have so clear in your mind. If it’s not so clear, that's still ok, just know how to handle this uncertainty and make it be not your problem, but your workstation's GPU affair.

This is the basic.

We humans are somehow limited in our ability to understand the world outside our brain cage. A few thousands years ago an elderly like me used to say “I hear and I forget. I see and I remember. I do and I understand.”

The wise man is still right even in the brave new AM world. If you really want to have a clear understanding you have to do.

Do experiment, make, dare, challenge the obvious, fail laughably, guess why, repeat until your guess is proven, iterate harder.

Build up your knowledge the bloody way, you will design better and better.

Q.

How can companies enable their staff to better understand when and how to adopt additive manufacturing?

A.

It’s a matter of understanding which is the value your customers ask for and which they would appreciate even if they are just not aware you can provide it.

AM as a whole is all about value, it’s a costly method of shaping material which requires the effort, the engineering effort, of making this worth the hardship of the tech, the math, the learning and failing and layering, lasing, sintering, heating, dripping, depowdering, buzzing and waiting to coalesce those bytes into reality.

AM escalates manufacturing from the effort and speed of machines (forging, drilling, molding, stamping, all the loud banging and heat flashing) to the silent and harsher effort of soundly conceiving.

AM adoption just follows the same scheme: it’s not a matter of energy, of engines capability, or simple calculations. As to make AM make sense, as to get you providing meaningful value through the shape of weirdly combined molecules, you have to fill the void of nature with ingenuity.

How can a company foster the ability of their technical staff to seize the low hanging fruit of meaningful AM made parts?

Set a path to refocus your engineering on customers’ needs while your staff gets acquainted with AM by investing time and money in a steep learning curve.

Exercise with simple problems, simple parts and gradually escalate complexity.

Make engineering a customers’ problem solving game, an added value quest rather than a hardware and process constraint mitigation exercise.

Of course it’s not tomorrow morning KPI but this needs to be the long journey perspective in a daily routine, we learn by doing and doing takes its time. Plan the route, assess, track, measure your goals, don’t give in, ask for help or counseling if needed.

Q.

Finally, what most excites you about designing for additive manufacturing and what are you looking forward to in the future.

A.

DfAM is not exciting, as I said it's addictive, so what do I seek for the future? I'm into it, so more DfAM ;)

I would like to thank Marco for taking the time to share a little about Add+It and their approach to DfAM.

If your company needs help in the acceleration of the adoption of additive manufacturing but do not have the experience or expertise in house to design and make a well informed business case, reach out to Marco and his team at Add+It Tech to explore how they may be able to help. Their infectious enthusiasm and pragmatic approach are a winning combination to help you on your DfAM journey.

All images copyright and courtesy of Add+It 2022