Exploring Digital Materials: with Marek Moffett of General Lattice

CDFAM Speaker Series with Computational Design Experts

In the latest interview of the CDFAM Speaker Series we talk to Marek Moffett, Co-Founder and Chief Innovation Officer of General Lattice, which explores the company's evolution, its lattice design and optimization software solution Frontier, and the consulting services offered by GL Labs and the software behind the design of Wilson’s 3D Printed Basketball Prototype.

Moffett also offers insights into the concept of digital materials and their potential applications while highlighting the company's participation in the upcoming CDFAM symposium.

For the complete interview with Marek Moffett, be sure to visit the CDFAM Symposium site, where you can access this and other conversations with computational design leaders, and gain further insights into General Lattice's innovative solutions and vision for the future of additive manufacturing including:

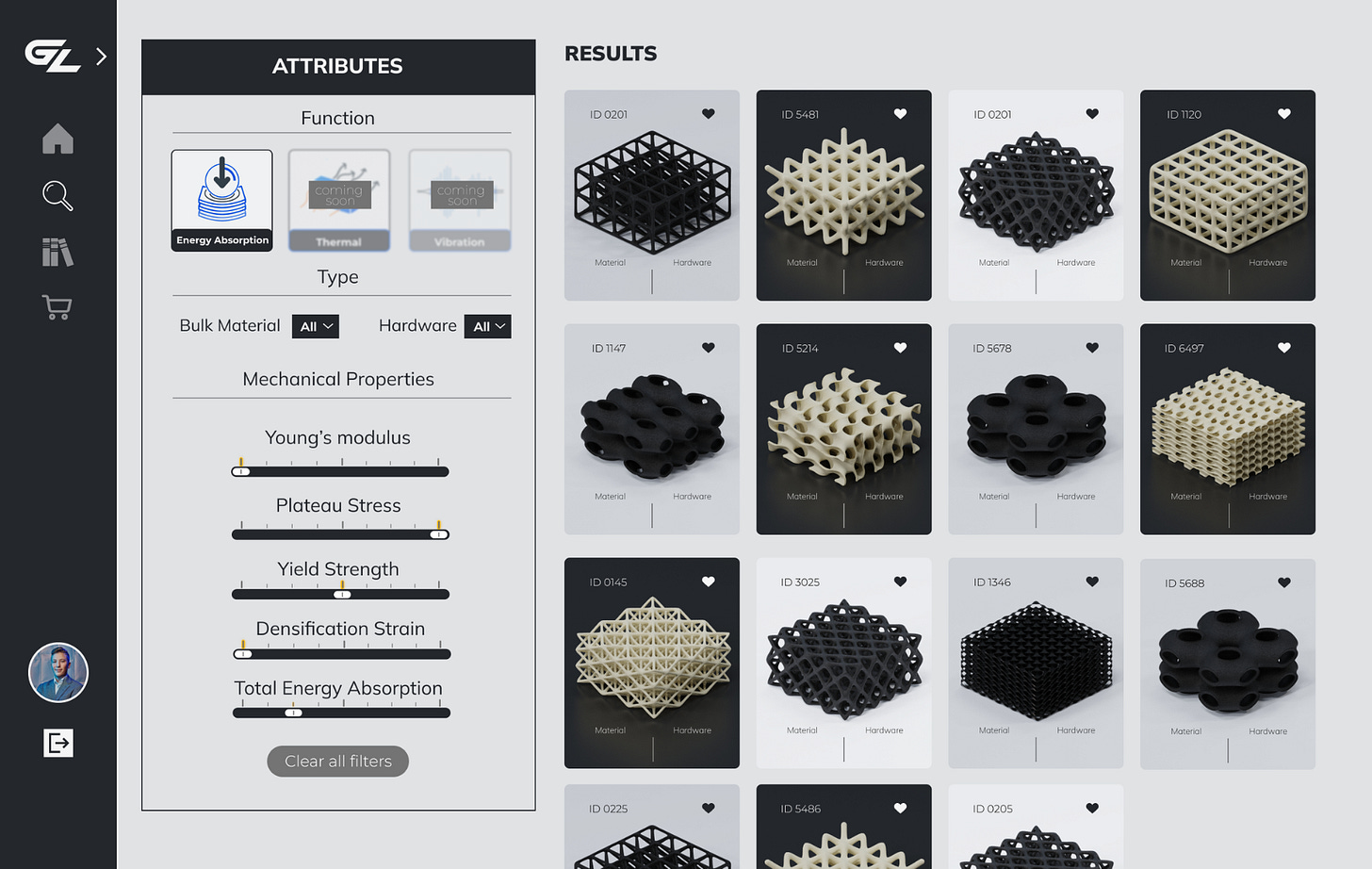

General Lattice's Frontier software is a lattice design and digital material platform that offers a library of quantified data and design tools for easy integration, streamlining the design process and accelerating product development cycles.

GL Labs, the consulting side of the business, has worked on a variety of commercial and government projects, with each project informing the development of Frontier and enhancing the company's ability to serve clients.

Digital Materials are a combination of geometry, material, manufacturing hardware, and mechanical properties, all of which are used to deliver full latticing solutions to customers, enabling them to create innovative and functional products.

At the CDFAM symposium, Moffett will present on ‘Digital Materials – Geometry and Data Combined,’ further exploring the concept of digital materials and General Lattice's role in their development and adoption.

Free subscribers can read the full interview with Marek Moffett of General Lattice on the CDFAM Symposium website or subscribe to read this and future articles.

Could you provide an overview of General Lattice, its capabilities, and what inspired you to develop this software?

Founded in 2019, General Lattice (GL) started off as a contract manufacturer working with photopolymer systems. As time passed, GL pivoted away from physically printing parts for customers and instead focused on lattice design and integration services through its special projects team GL Labs.

After spending over 4 years supporting a variety of customers across industries, GL continuously found itself starting every project by printing swatches of lattice, testing them, and down selecting before reaching an optimal solution. This repetitive process ultimately led to the development of Frontier, a Digital Material Platform that provides a searchable library of quantified data in advance of the design stage (coming soon), along with powerful design tools that make Digital Material integration remarkably easy.

In addition to ‘Frontier’ software development, your company offers ‘Labs’ consulting services. Could you share more about the types of projects you've been involved in and the range of services provided, and how does each side of the business inform each other?

GL Labs handles special projects both commercial and government.

Our most recent commercial project was a collaboration with Wilson Sporting Goods to develop the Airless Prototype, an additively manufactured basketball featuring a complex lattice architecture. Labs worked with Wilson to integrate a functional structure that would meet three main objectives: a specific mass, a certain amount of rebound, and hemispherical symmetry. Over a few months, Labs was able to generate and optimize a Digital Material that met all of the aforementioned criteria.

In addition to computational modeling, Labs utilized General Lattice’s extensive SME network, collaborating with EOS and DyeMansion to achieve the best possible result. Recognizing and identifying key partners in every stage of the New Product Development cycle is critical to Labs success, and the Airless Prototype is a fantastic example of this.

Our most recent government contract was awarded through DEVCOM Soldier Center out of Natick, Massachusetts. The contract called for Labs to deliver a software tool that would suggest and generate lattice samples relevant to a mechanical property query.

The workflows and data collected from this project kicked off our development of Frontier. The data sets collected have also been used to inform some additional client work and dramatically accelerate product development cycle. The more data we can collect, the better we can serve our clients — whether through their own integration with Frontier or with the help of Labs.

In your CDFAM presentation titled ‘Digital Materials – Geometry and Data Combined,’ you discuss the concept of digital materials. Could you explain what you mean by this term and how your company contributes to their development and adoption?

GL defines a Digital Material (DM) as: a geometry paired with a material, manufacturing hardware, and respective mechanical properties which is represented by a unique ID.

A DM is used with the DMI to deliver a full latticing solution to the customer.

Over the years, GL has developed an internal operating system (GLOS) which enables streamlined sample set generation, profiling, aggregation and interpretation. GLOS is the backbone of Frontier and is designed to allow ingestion of large volumes of DMs with the ultimate goal of populating the DML with all the relevant data we can.

How can engineers determine when it's time to explore using 'digital materials,' and what are some applications where you've seen significant traction?

One of the goals of the DML is to deliver relevant comparisons of our DMs to materials used today — if we can provide this data publicly we hope to see a wider exploration.

There have been a range of applications we have seen interest in: foam replacement, impact dampening, vibration reduction, thermal management, light weighting, etc.

With so many application verticals on the horizon, in the short term, we will be focusing on foam replacement applications such as protective padding and insulation.

When engaging with customers, do they usually provide performance data and requirements, or is that something you often collaborate on to develop together?

Generally, a customer will provide performance metrics they are looking to meet. We take that data and search our DML to see if we have any relevant DMs. If so, we can begin to move forward with design space integration. If not, we typically will develop a design of experiment specific to the client needs and run it through GLOS.

In design and engineering, software integration is crucial. Could you describe some of the software workflows that your customers and team have used in conjunction with 'Frontier,' and explain how data is transferred between these platforms?

Currently, we have seen a lot of success with having a fine level of control over the resolution of our structures enabling workable file sizes while using traditional import/export workflows.

As we move forward, we are evaluating the best ways to go about addressing such large amounts of data and the translation to other key softwares required in potential lattice workflows.

What motivated General Lattice to create its own material database? Could you give an overview of the database under development and explain how hardware and materials companies can contribute to this project?

Our motivation came from over the years of offering Lattice as a Service. The two common asks from clients were:

1. Can you show me the lattice that will act like “this”?

2. Okay great, can you now put “this” lattice in our design space?

This led to the development of Frontier which allows users to search for their desired lattice and integrate it.

For success, we need the most amount of relevant data we can. This is made possible through key material and hardware partners. Currently, GL has early partner involvement from companies such as EOS, BASF, and Photocentric. Although initial data in the DML will be generated by GL, in the future GL is considering third party contributions to the database.

Lastly, what do you hope to gain or achieve through your participation in CDFAM?

I hope to connect with industry leading peers and potential collaborators while sharing the developments of GL’s solutions we aim to bring to the market in the near future; ultimately paving the way for Digital Materials to be adopted for production applications.

To learn more about General Lattice software and services reach out to Marek and the team and/or meet them along with other experts in computational design and advanced manufacturing at CDFAM in NYC June 14-15 2023