Greener By Every Fold. Strength In Every Curve. Interview with Julia Hannu – STILFOLD

Industrialising Kirigami at Scale

Ahead of her presentation at CDFAM NYC this year, Julia Hannu of STILFOLD shares how the Swedish design and technology company is focusing on sustainable manufacturing through origami-inspired sheet metal forming.

By applying both straight and curved crease folding to flat metal sheets, STILFOLD creates lightweight, high-strength structures that reduce material use, energy consumption, and part count.

In this interview, Julia outlines STILFOLD’s approach to scaling curved-crease folding from a research concept to a repeatable industrial process.

She discusses the geometric and material challenges, the in-house hardware and software systems driving development, and the range of applications where folded metal structures outperform traditional manufacturing methods.

From automotive frames to architectural panels, STILFOLD is making folding a viable path for greener, more efficient production.

Can you start by introducing STILFOLD and what you’ll be presenting at CDFAM regarding your origami-inspired manufacturing approach?

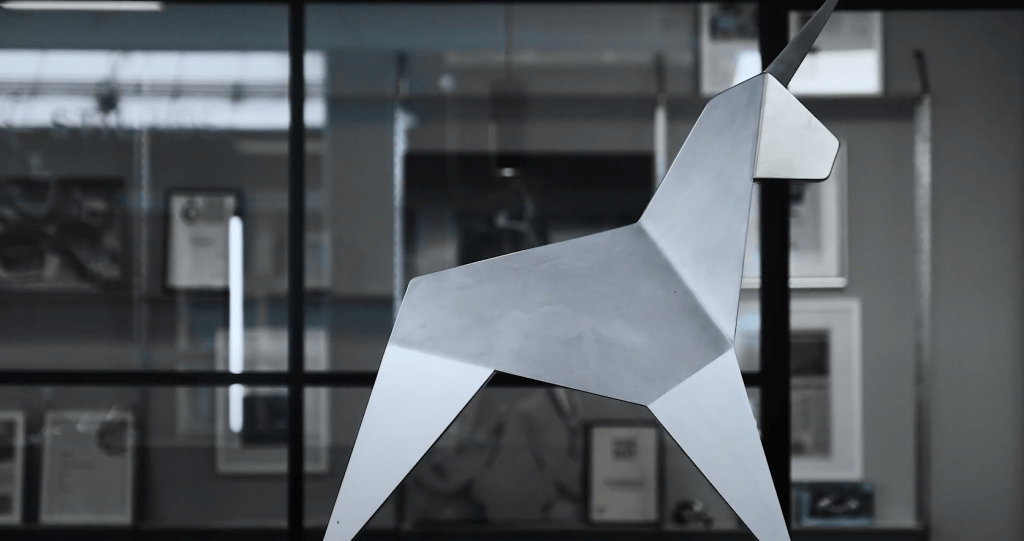

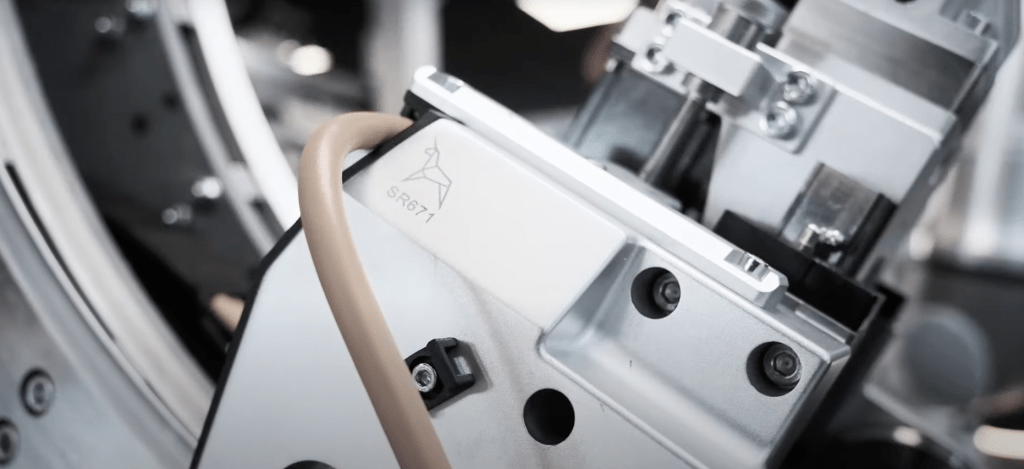

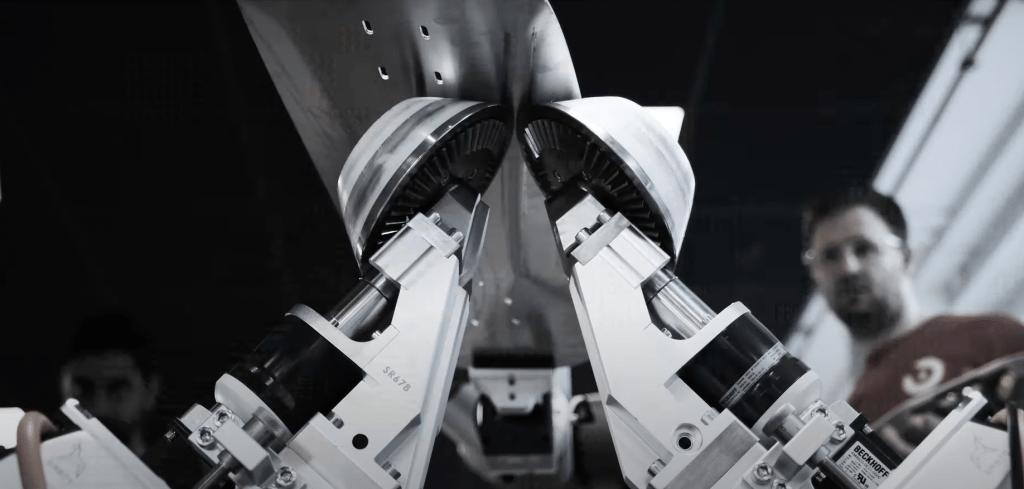

STILFOLD is a Swedish design and technology company pioneering the use of origami principles in industrial manufacturing. Through cutting and folding, we transform flat sheets into high-strength, lightweight complex structures. Working with both straight and curved creases we can apply the full language of paper folding to metals and take it from design to production.

At CDFAM, we are presenting our process and how we are industrializing curved folding as a scalable production method. This to reduce part count, weight and energy use, while streamlining production and Logistics.

What are the core geometric and material challenges involved in transitioning curve crease folding from a research concept to a scalable industrial process?

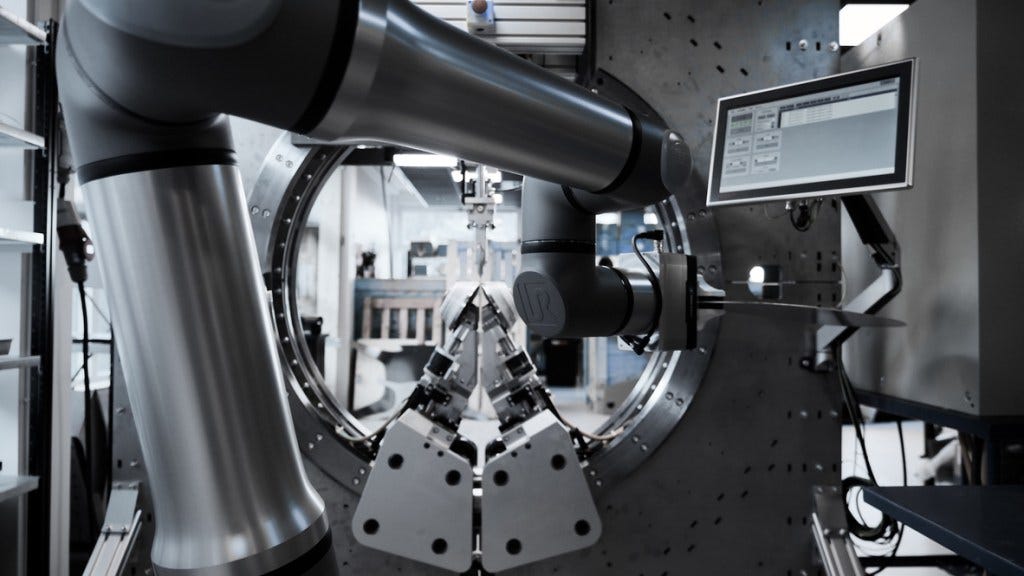

We’re making physical objects, so everything comes down to the geometry, process, and material behavior. Especially curved creases requires precise control to be able to design complex three-dimensional structures to meet certain requirements while keeping all surfaces developable. Also, to produce it we’ve developed the hardware system ourselves which has it’s own set of challenges with machine construction and toolpaths.

We’re currently scaling the process into industrial production which means repeatability; the sheet must flow every run without buckling or uncontrolled spring-back.

What types of products or structural applications are best suited to STILFOLD’s folding-based manufacturing, and what makes them a good fit?

Anywhere a thin metal shell outperforms a composed or solid structure. Think chassis, structural body sections, petal or blade forms, battery enclosures, drone frames or platform. Whenever you like to gain stiffness without mass, skip expensive press tools or lose fasteners and welds. Folded forms also carry their own aesthetic qualities which works well for exposed surfaces such as architectural panels.

How can designers or engineers evaluate whether folding as STILFOLD implements it is an appropriate solution for their specific design or manufacturing challenge?

First, look at the geometry. Could you rethink this shape in such a way it could be folded rather than formed? As you’ll need to rethink the geometry as a folded developable. Then look at the assembly. How many parts and welds could disappear if replaced with a fold? And when you add it all up in cost, lead time and risk, does folding outperform a new die set or an additive process? These are the types of questions you need to ask yourself. It’s a way of thinking though which might be unfamiliar so we often consult to identify suitable parts.

What software tools does STILLFOLD connect to, and the digital workflows STILFOLD uses to design and simulate folding patterns, particularly for curved creases?

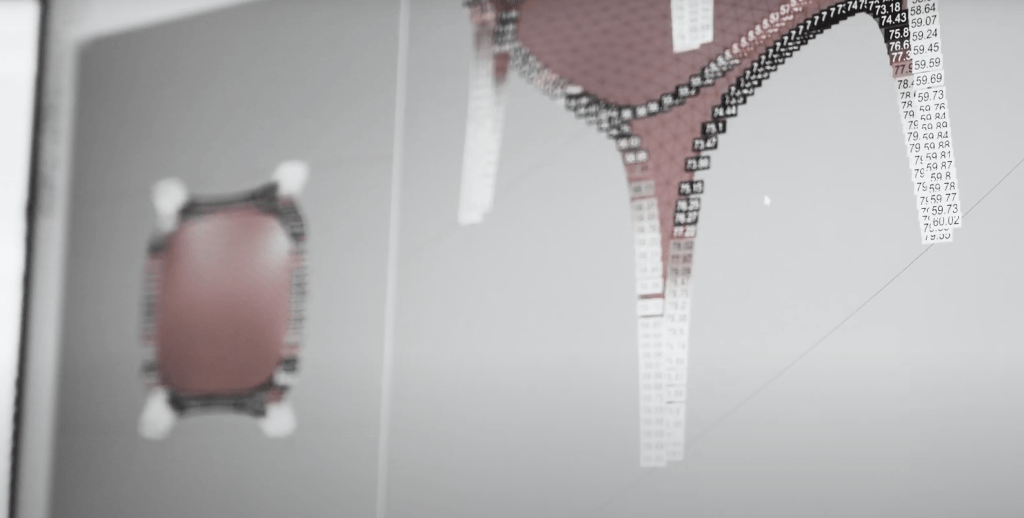

We like to keep our loops short, going from idea to prototype and production. So it’s all about defining that fold pattern, which can be translated into machine and robot instructions, in such a way that you meet the product requirements. Especially for curved creases the geometry quickly becomes more complex as we are building networks of connected developable surfaces, requiring full control over our crease curves.

The digital process is iterative between the flat pattern and the folded geometry, where analysis and simulations guides how to place and shape the curves to balance strength, material behavior and manufacturability.

Ultimately, our software needs to help us verify manufacturability as early as possible in the design process, to close the gap between the digital and physical.

How do you handle data flow between design, simulation, and physical fabrication, especially when integrating custom folding algorithms with production systems?

We make a lot, test a lot, and learn from every run.

From the digital model we extract fold patterns and crease parameters that, together with material data, set machine and robot instructions.

We compare the process and final object with our digital model and simulations to evaluate how material and process dynamics influence the result. That feeds back into production and our digital tools to, when needed, detect issues earlier.

What do you hope to share with and learn from the CDFAM community regarding the intersection of computational design, manufacturing, and sustainability?

We want to share key insights from our practical applications of curved-crease folding and how it can be a greener, shop-ready alternative for production.

At the same time we look forward to learning from this community, to explore better ways to connect computational design with forming limits and material models, and hopefully how sustainability can be measured and linked between digital design and real manufacturing as we need to tie intent to factory reality.

STILFOLD’s work demonstrates how computational design and folding-based fabrication can open new possibilities in sustainable, scalable manufacturing. Whether you’re exploring curved-crease geometry, kirigami, or the intersection of digital tools and material behavior, Julia Hannu’s session at CDFAM NYC will offer valuable insights from the front lines of industrial innovation.

Don’t miss the opportunity to connect with Julia and others pushing the boundaries of geometry, structure, and sustainability. Join the CDFAM community in New York City to learn, collaborate, and shape the future of computational design.