Interview with John Barnes: Helping people journey from DfAM awareness to expertise.

DfAM Training and Courses with Barnes Global Advisors & Purdue University

John Barnes and the Barnes Global Advisors have been helping companies accelerate the adoption of additive manufacturing since 2017 through advising, their own Design for AM Training as well as an AM certificate in conjunction with Purdue University.

John and his team have decades of experience at the bleeding edge of the development and adoption of additive manufacturing which informs the coursework designed to accelerate the learning process from awareness to expertise.

John has been kind enough to answer a few questions about the training courses along with how people and companies can accelerate their DfAM journey.

Q. Can you tell us about the kinds of courses you offer both for individuals with the online course in collaboration with Purdue, and the team based courses you offer to companies?

A. TBGA offers several different types of AM courses and workshops, but the more design-intensive ones are provided to individuals via the Purdue University AM Certificate and to teams with our Designing for AM course.

The Purdue AM Certificate is 100% online, designed for working professionals and individuals to access whenever and wherever they desire. The videos and coursework are entirely online.

The Designing for AM course is delivered live, either virtually or in-person, to teams looking to upskill their workforce.

Q. At what level of prior knowledge of additive manufacturing would be required to take the courses and what would indicate that an individual or a team could benefit, and what roles at a company could benefit?

A. Both courses are designed to provide an individual with a college degree but with little or no knowledge of AM and elevate them to a proficient level to choose the right form of AM for their requirement, understand the design principles and build a business case.

Q. What is the structure of the courses and what is covered?

A. The Purdue AM Certificate has two core courses: AM Essentials and AM Technologies and Materials. The individual can then choose an elective for the Level 1 certificate or two electives for the Honors certificate. The electives are: AM Design and AM Business & Economics.

The Designing for AM class follows a similar structure but includes: AM Basics, Technologies & Materials in AM, Design including Modify for AM (MfAM), Design for AM (DfAM) and Process Economics. Since this class is live and team based, we go into deeper detail and can tailor more towards the company’s experience, application requirements and likely use of AM.

Both courses are holistic, meaning that design for AM includes concept through to the finished part. The courses are agnostic in that we provide information on all forms of additive manufacturing alongside how they might compare to legacy manufacturing methods. We also discuss the business side of how one might construct a business case, or value proposition, to use AM.

Q. Can you describe the maturity model you use to analyze both AM processes and applications?

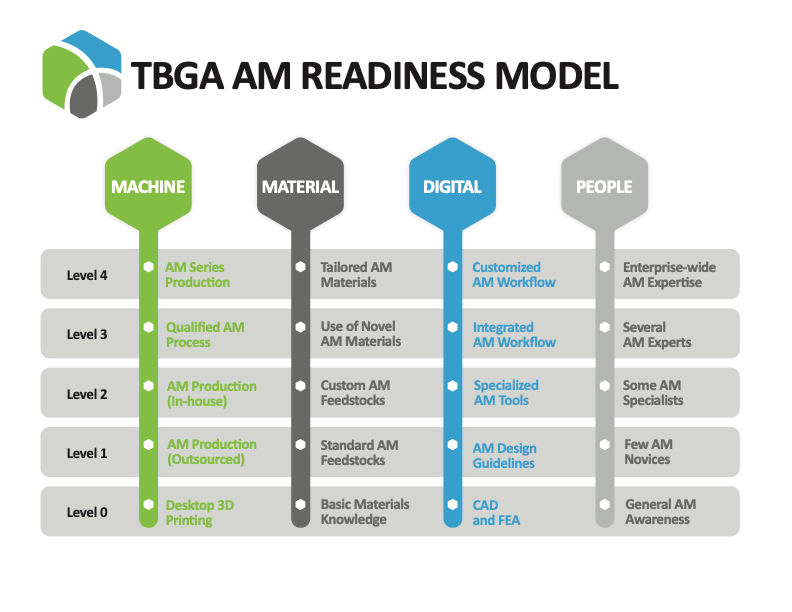

A. TBGA created several models that help break down the complicated AM space into easier to digest pieces. The TBGA AM Maturity Model describes the product requirements and commensurate skills/knowledge/support that an enterprise requires to implement at that level.

Whereas Level 0 is using AM for prototypes and Level 1 is for tooling, these are indirect uses and therefore have fewer requirements. At Level 2, AM is being used to manufacture the part, so the necessary skills, data and qualification plan needed to ramp up are much higher. At Level 2, the design space is more restrictive and MfAM is more critical. Levels 3 and 4 address part consolidation and AM-enabled design, or where we describe the design opportunity space is more open.

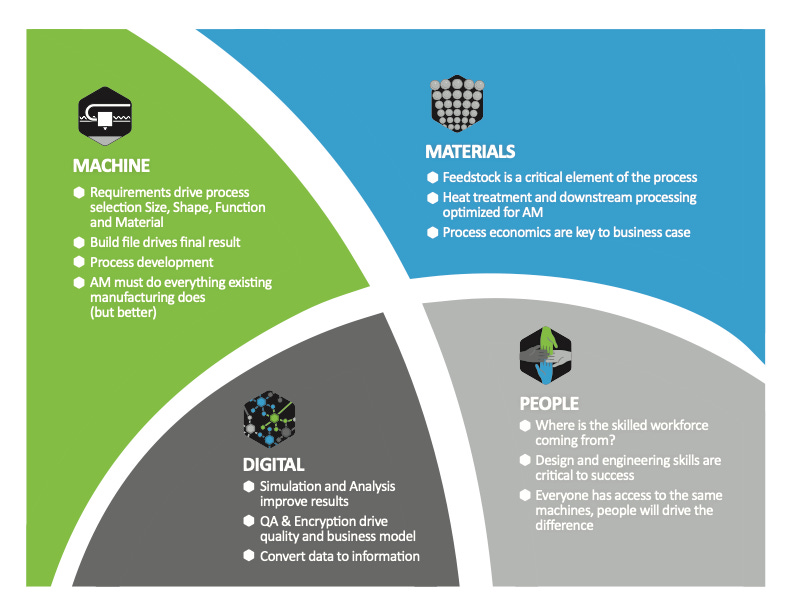

We have further developed the TBGA AM Readiness Model to expand the Maturity Model and add detail in four key areas: Machines, Materials, Digital and People.

Q. What are the takeaways from the course, what level of maturity would you consider someone who has completed the coursework?

A. The graduate from either course comes away with a strong appreciation of the strengths and weaknesses for the various forms of AM. They can describe how a layer is formed, how the material is applied and how the energy is applied and, therefore, can construct a process specification.

AM is a team sport, so different backgrounds will appreciate different aspects of designing for AM, but by focusing on the product requirements, and the capabilities of the AM process a team can be assembled to cater to the holistic design and process.

Lastly, a fundamental understanding of process economics is vital to creating a business case and a value proposition. After all, if AM isn’t solving a problem, why use it?

Q. What are some of the common misconceptions you see from people coming into the courses?

A. The first is that people look at AM as a "print & go" solution; they come away from our course with an appreciation that AM is way more than just the printer. Two is more typical with the experienced engineers, that we are there to convince them to use AM, which we are not.

We are not there to evangelize for AM, but we do want you to be able to articulate why you aren’t using it and, as AM technology is maturing quickly, when and why it may become viable in the future.

Q. What are some of the most impressive transformations of understanding you have seen from people coming out of the courses?

A. As an instructor, it is incredibly rewarding to lead learners on a journey and experience their big "a-ha" moments; we've seen these transformations happen both at the individual and business level.

One learner, Tyler, used the insights from the course to construct a business case for investing in AM which launched his career in a new direction leading a new AM initiative at his company.

Often, we maintain relationships for years as individuals change jobs or have new questions.

For one enterprise, we started with a 4-day Designing for AM intensive course and quickly realized they needed a complementary shorter course for program and business leaders focused on AM projects; this course opened their eyes to AM's impact on the product lifecycle and the importance of considering AM early in the program during system level design.

Another business pulled together a multi-functional team who identified $2M in annual savings potential through the applied learning exercise. The ROI for our course is incredibly high, typically in excess of 40:1. The leadership wins by (1) investing in their employees and (2) with cost savings or new products.

Q. What are some of the common key takeaways you see from people coming out of the courses?

A. The validation that AM is not the answer for everything, but that it can be the best answer for certain applications with the right value proposition and design approach. In their independent development efforts, many have encountered physical constraints of the process that are undersold at tradeshows, and eventually become discouraged about the technology when it doesn’t deliver as promised.

Our courses emphasize the importance of a comprehensive approach to AM that considers the many key factors that can make or break a project, ahead of time, before it’s too late when all budget and/or appetite for the technology is gone.

Q. How can people get started with the courses?

A. For the Purdue AM Certificate it is as easy as registering on our website and they can get going right away.

In celebration of our 5th anniversary, we are offering $500 off registration until August 5, 2022.

For the live Designing for AM course, we can be reached via the website or directly to align our offering to the need. We also offer tailored learning where we build specific learning content based on the enterprise's targeted learning outcomes in a format that is ready to load into their Learning Management System.

Q. Anything else you would like to add?

A. Overall, while AM continues to make an impact in manufacturing, we are still a ways off on knowing how to leverage the process for what it can do in any widespread manner.

TBGA leverages our experience qualifying and employing different AM processes to provide a realistic, sensible approach to solving problems with AM based on our real-world experience.

We also have unique visibility into the state-of-the-art for the industry as the leading AM consulting team. We keep a steady pulse on all of the incredible innovation that is happening in the industry, and aim to share those stories to inspire further development among the talented training audience we get to serve.

Thanks to John for taking the time to develop the DfAM courses and for being an advocate for the importance of DfAM education.