Interview with Nolan Kim on Biomechanical Engineering & Computational Design for AM

And the importance of physically testing prototypes for performance.

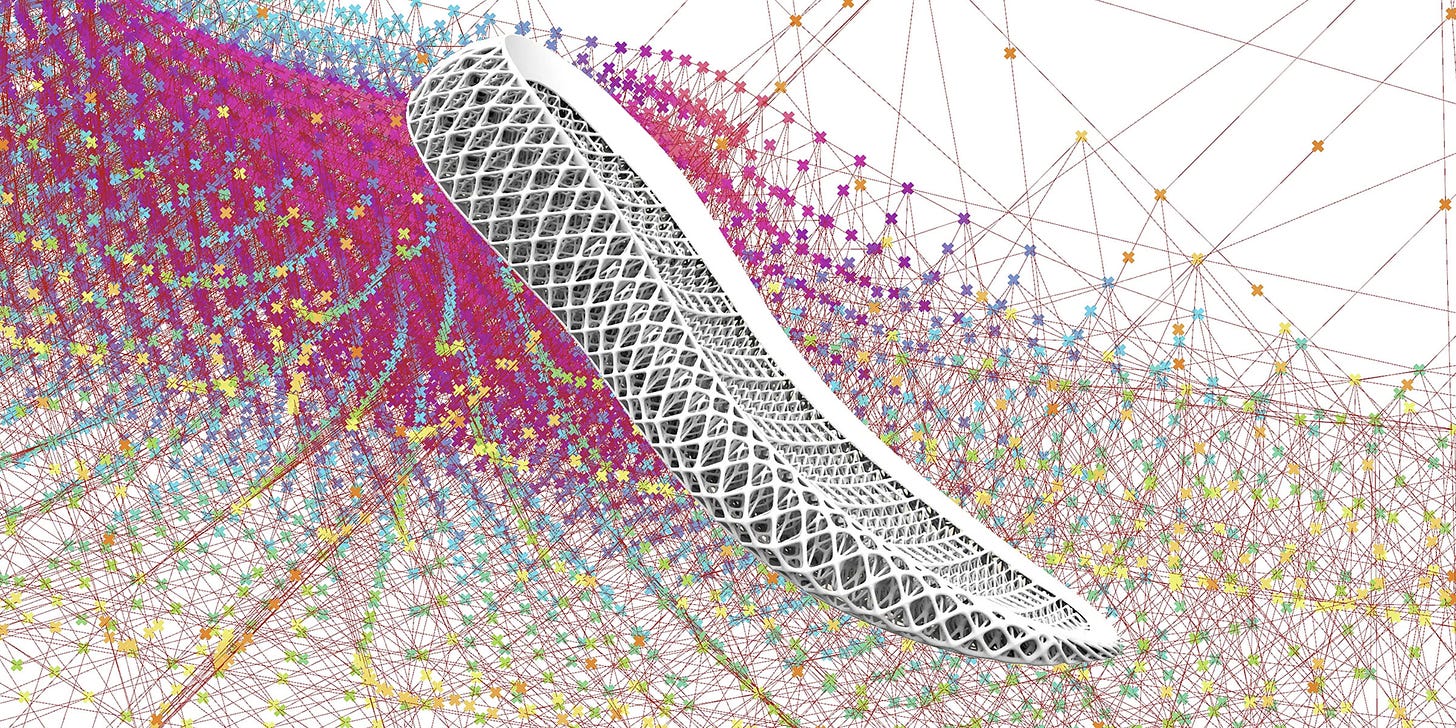

Footwear design has been at the forefront of additive manufacturing and computational design for a number of years, from Onur Yüce Gün’s work on multi-objective optimization and part to whole explorations through to the Adidas Futurecraft series now in production.

This interview follows Nolan Kim’s journey through computational DfAM of running footwear started with his education in Biomechanics Engineering with some experimentation with a Formlabs 3D printer through to a role at Desktop Metal exploring the capabilities of their polymer portfolio.

Can you tell us a little about your education and how you came to computational design for additive manufacturing?

My undergraduate degree was in Biomedical Engineering at Boston University. I found the studies engaging, but once I had actually interned at a biotech laboratory, I realized that this field wasn’t something I had any practical interest in.

For the final year of education, all engineers were to undertake a project from a given list — researching under professors, teaming up with local start-ups, etc. A friend had been following innovations from New Balance and Adidas and suggested pitching our own project. We submitted a proposal to the engineering department to investigate ‘enhanced running performance through lattice midsole design’. They approved the idea and granted us a Formlabs Form 2 SLA printer. This was my introduction to additive design and manufacturing.

As the Covid pandemic began, I spent all my time in quarantine learning more 3D software and curating personal projects. Soon after, Desktop Metal invited me over to discuss some projects they had in mind and by the following morning I had a table in their office. As their material portfolio and line of printers began to expand, I was able to really sharpen my understanding of computational design and experiment with a variety of design applications.

Your portfolio includes a number of footwear design projects. What about printed footwear interests you and why do you think it’s leading the way in the adoption of computational design practice in additive manufacturing? What are its limitations?

For me, it’s specifically 3D-printed running footwear that’s compelling. There is a standard of performance that needs to be tested and met. It’s not enough to create a structure that’s vaguely comfortable and durable.

It’s an amazingly unique blend of biomechanics, marathon running, and computational design — a really nice intersection of research, athletics, and creativity. There is a really strong interconnection from data, to form, to behavior. It’s a design whose influence on athletic performance is extremely measurable.

For instance, a 100g reduction in shoe weight has shown to improve marathon performance by 1%. There is no other sport I’ve seen with such direct connectivity between design and objectively improved athleticism.

By convention, shoe midsoles are made from injection molds. A solid, uniform shape with structural innovation limited to its outer perimeter. What makes a 3D-printed element into this space so enticing is its ability to gain control of the midsole’s interior space. This opens up entirely new possibilities of form and design freedom which, ideally, will subsequently lead to entirely new functionality and behavior.

While additive offers a structural revolution, its material portfolio still can’t quite match the lightweight responsiveness of traditional foam.

Computational DfAM for industrial designers is typically less simulation driven than for mechanical engineers, what data do you use to drive design specification, constraints and iteration?

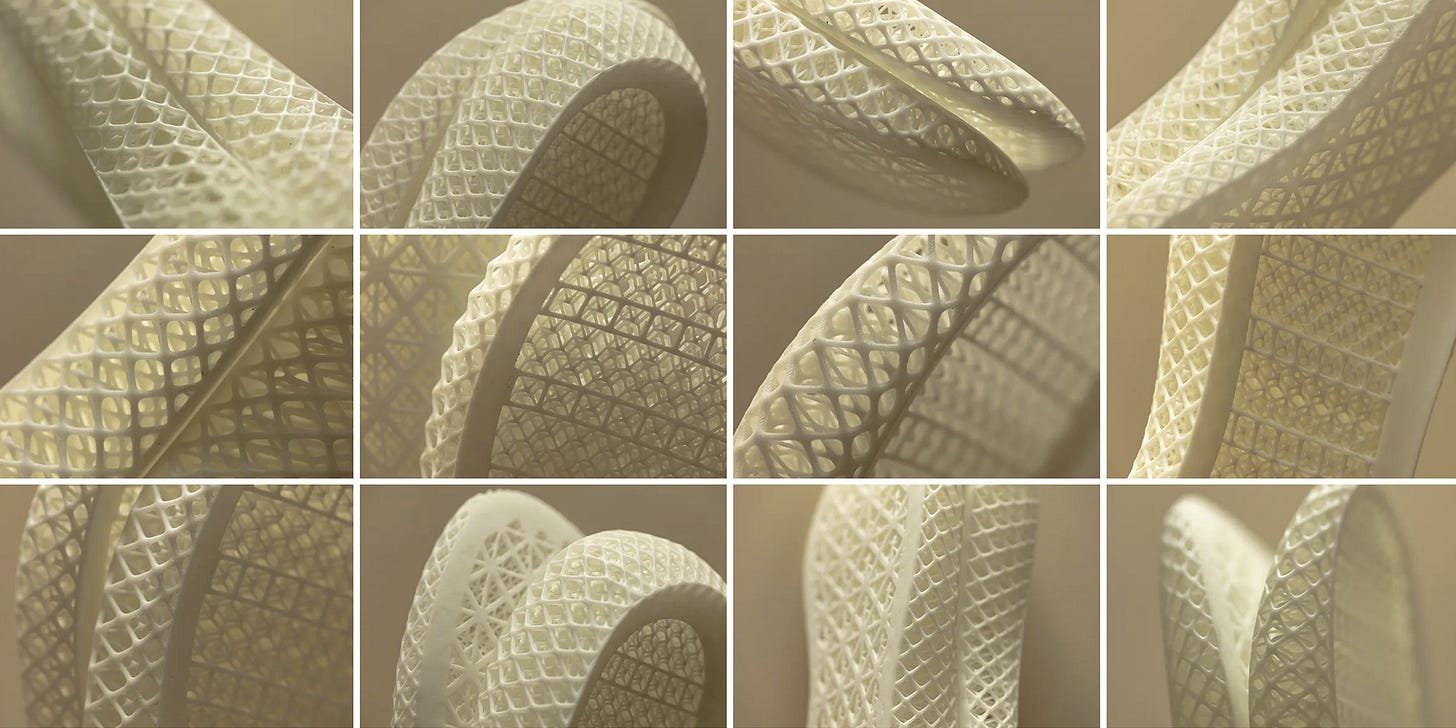

I’ve been fortunate enough to have hands-on access to many printers and materials, so I’ve been able to build a physical library that ranges through different lattice types with varying feature configurations.

Nothing beats having tangible samples.

This has helped give a general gauge of reasonable feature tolerances to work within depending on the material stiffness. Some new software has begun building geometries based on behavioral descriptions instead of specific numerical parameters. This method could potentially offer a good starting point, but, of course, any structure with empirical behavioral constraints will require proper mechanical testing.

The importance of physical samples also lies in events that occur during the printing process that are not accounted for in the software.

For instance, with top-down resin-based machines, parts tend to swell up overtime leading to deviations from the intended design. I always measure the actual weight and feature sizes of the final part, compare it to the software’s measurements, and adjust accordingly.

There has been a number of new 3D software emerging in the industry. To you, what makes a particular software useful and what part of your workflow would benefit from some new approaches?

The ideal design software maintains a healthy balance between assistance and controllability. Most of the emerging programs I’ve seen prioritize a completely hassle-free design process. Carbon’s new design engine undertakes a lot of the advanced computing and thought-processing in the background and only presents the user with extremely basic input parameters. A case of over-assistance and minimal controllability. For users who only need simple sample pieces and general infills, this produces neat results with little effort. But the moment any detailed alterations need to be made, there lies a large and, more importantly, inaccessible void between the intended design and the final product.

In contrast, the Hyperganic Group stands at the opposite end and encourages users to build their needed design system from scratch. It’s an extremely powerful tool with well curated tutorials and useable frameworks but requires a foundational understanding of C# programming. Perhaps, for many, a case of unbound controllability with limited assistance. Of the newer software, nTopology manages the best stability between the two traits but still finds limitations due to its exclusion of a native modeling ecosystem.

Of all the software I’ve come across, the combination of Rhino and Grasshopper, a package of modeling and visual programming within one program, has been most dependable.

Hardware has improved with larger machine build volumes, modeling has advanced with micro-architected geometries, yet print preparation, the connection between the two, is beginning to lag behind.

A structure both large and complex produces a mesh of an almost unusable file size. I’ve waited over half an hour just for a part to simply load into, or completely crash, a slicing program.

Technologies similar to Metafold, who are developing meshless exporting and more conscious integration with individual printers, are becoming more urgent. Another process lacking in advancement is support generation. Structures with internal openings, such as lattices, are interpreted poorly by ‘auto-generate’ support features and lead to tedious, manual intervention. These programs offer either speed or functionality, never both.

What are you most excited about exploring in computational design for advanced manufacturing?

As each year passes, additive manufacturing is straying further away from its perception as a simple prototyping tool and entering into a reality of scalable manufacturing for fully functional products.

ICON Build is developing truly beautiful 3D-printed homes in Texas as well as leading an initiative for printing infrastructure in outer space. Automobile companies are readily adopting printed parts and additive’s ease of customization are finding its way into the medical field.

This transformation in manufacturing, in turn, brings about an evolution in design. The pairing of these advancements allows for structures to operate well beyond aesthetics and even beyond traditional functionality. There are new sights to create forms that are adaptive, responsive, and lively. The convergence of biomimicry and 3D-printing has been an emerging field that has been gaining more attention, particularly through the efforts of Neri Oxman’s team. Following the mantra of ‘materials are expensive, shape is cheap,’ we are positioned better than ever before to devise truly reactive assemblies. Structure no longer has to be a rigid construction of cuts and molds.

With generative approaches and computational tools, designs are now mindfully ever-changing.

Reach out to Nolan if you have a project that requires biomechanical engineering and computational design.