Mark Burhop on Communicating Complexity and Additive Manufacturing at Siemens

CDFAM Speaker Series Interview

While additive manufacturing has unlocked geometric freedoms not possible with subtractive manufacturing processes, designing and communicating the potential complexity is not always possible with design tools that were developed to create much simpler geometry.

Mark Burhop, Research Engineer and 2022 Inventor of the Year at Siemens has been exploring this topic, helping to advance techniques to create and communicate geometry in a programatic manner that may actually help to ‘make complexity free’.

Mark will be speaking at CDFAM Computational Design (+DfAM) Symposium about this topic in NYC so we asked Mark a few questions about how he got started investigating this topic, what problems it seeks to solves and a little about what he will be covering at CDFAM in June.

Congratulations on being named the 2022 Inventor of the Year at Siemens for your cutting-edge work in the representation, design, simulation, and manufacturing of complex meta-materials.

Can you share with us what drew you to this field of study and give us an overview of the work you and your team are exploring?

Five or six years ago, DARPA realized that design software was not keeping up with the rapid changes in manufacturing, especially additive manufacturing.

Suddenly, you could fabricate incredibly complicated products but the process of designing, representing, simulating, and optimizing the design was either really hard or impossible.

Funded by DARPA, Siemens put together a team with some top researchers in academia and industry to develop new technology to address this problem. It was very successful and is leading to all types of new innovations.

The Inventor of The Year award was really in recognition of the open innovation we all did in this area. It will be exciting to talk about it at CDFAM.

The phrase 'complexity is free' is often used to describe how additive manufacturing (AM) can sometimes reduce the cost of manufacturing complex parts due to machine time and material usage. However, there are also trade-offs. In your experience, where do you believe 'complexity is free' in AM and where do we pay for it? Can you provide some examples and insights on this topic?

In additive manufacturing, the process of sending machine instructions to the 3D printer (usually GCODE) is the same whether it is a simple cube or complex lattice. Contrast that to trying to do the same with some other manufacturing technique like CNC, or bending sheet metal, or casting. The manufacturing complexity there expands with the part complexity. So, in a lot of ways, you do get complexity for free in additive manufacturing. It is not 100% true, as many technicians will tell you, but elements are.

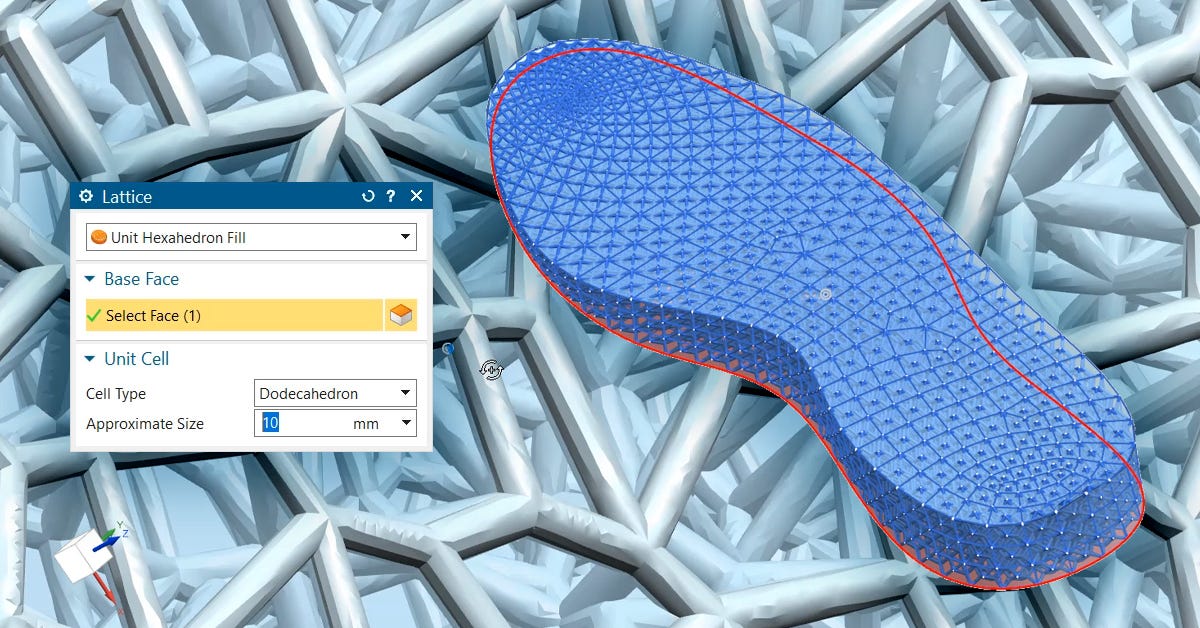

However, try to create or load an ultra complex part into the CAD systems of 10 years ago and you are in trouble. Maybe you could pattern some geometry for some repeating structures but traditional solid modeling was not the best way.

The use of faceted representations more recently added some new capability, at the loss of some accuracy, but even that has limits and can’t cover the full range or AM capability. It is the same with voxel (3D pixels) representation. What is a designer to do when they can model 10^5 features but really need 10^10 or beyond?

Complex lattice structures are an important aspect of your work, and you have been involved in several innovative projects in this area.

Can you share some of these projects with us and elaborate on how you utilized the 3MF file format to store and communicate the necessary data for manufacturing these structures?

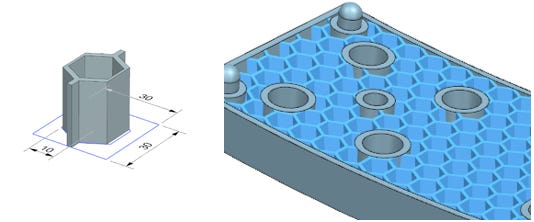

One of the best examples of complex geometry in a design are lattices, so this was one of the primary representations we looked at. While we could represent them very efficiently, you really need to be able to move them to other software for analysis, optimization, and manufacturing.

As I mentioned above, existing methods (Solid models, facets, voxels) are simply not good enough.

Fortunately, 3MF supports more than just facets. In the case of lattices, you can store a graph of the lattice. This is nodes where they connect and radii of the beams at each end. This is a much more concise representation with less loss of accuracy.

Further, CAD systems like Siemens NX and simulation products like Siemens SimCenter can read the lattice representation and create a 1D mesh for simulation from a simple import of the 3MF file.

For example, we looked at creating optimized lattices in ship design where the outer hull receives a number of different forces. The 3MF lattice extension and API libraries provided by the 3MF consortium made it very easy to move these designs around between commercial software and our research software.

The 3MF consortium is expanding its scope to include implicit representations for communicating complex structures beyond beam lattices, such as Gyroids and other TPMS structures. In your opinion, what benefits do you think the efficient use of these structures in design will unlock?

Can you provide some examples and insights on the potential impact this could have in your research and on the industry?

Being able to send conic beam lattices to other software is useful, but that is not the only example of “hyper complex” design. What if a designer uses beams of a different shape? What if they want to use “2D” surfaces like morphing gyroids? They are in trouble as there is no easy way to get these designs to other software. You have to also be able to run analysis and optimization, and slicing software. This is why it is important to continue to advance the 3MF standards.

Implicit functions and surfaces are nice ways of addressing some of the problems above. They have clear concise definitions and we can combine their mathematical fields to create all types of structures that are hard to represent in other formats. It is the first logical step to supporting in 3MF after the lattice extension and what I’m looking most forward to in future standards.

We are looking forward to having you as a speaker at the forthcoming CDFAM Symposium in New York City. Could you provide us with a preview of the research you will be presenting, and what key takeaways attendees can anticipate gaining from your presentation?

I think we have some interesting research related to programmatic representation and manufacturing to address all the problems we discussed above.

Equations defining implicit functions are very powerful, but what if we take it to the next level? What if we represent geometry with a program? The program can encapsulate mathematical equations and fields like above, but also brings in programmatic constructs like looping, if/then and sequential operations.

What are you most excited to learn and take away from this CDFAM?

There is just so much going on in this space right now. Many people have different takes on “implicit modeling”, algorithmic modeling, and computational design. I’m interested in hearing everyone's opinions and ideas on this.

There are also good use cases in everything from space travel to protective equipment. I’m interested in hearing about the latest ones, what advantages the designers have gained in using new representation technologies, and what problems still need to be addressed.

Any last things you would like to add?

Siemens Technology is a research organization. We started this discussion talking about our partnership with universities and others in this industry.

I expect CDFAM will be a great place to find partners for future joint research and open innovation.

Anyone wanting to collaborate should definitely reach out or come talk at CDFAM!

For anyone wanting to learn more about the research Mark and his team are undertaking as well as presentations and networking opportunities with leading researchers, engineers and developers of computational design tools register to attend CDFAM 23 NYC, June 14-15.