On Smoothing the Rough Edges: Evaluating Automatically Generated Multi-Lattice Transitions with Machine Learning

Interview with Martha Baldwin - Carnegie Mellon University

Martha Baldwin is a PhD researcher at Design Research Collective in Dr. Chris McComb's Lab group at Carnegie Mellon University. Her recent paper entitled Smoothing the Rough Edges: Evaluating Automatically Generated Multi-Lattice Transitions, written with Nicholas A. Meisel, Christopher McComb investigates the performance of a lattice at the intersection between multiple cell types.

Much of the existing lattice performance research (and software) focuses on a single cell type and parameters, but the value of meta-material design often lies in varying properties and performance volumetrically, and what happens at the intersections and blends between these cells is not well known.

Martha’s research using Variational Autoencoders initially with a 2D strut-based dataset builds a framework for 3D lattice structures in future research.

Could you start by telling us a little about your Ph.D. research and what led you to investigate multi-lattice structure transitions described in your recent paper, ‘Smoothing the Rough Edges: Evaluating Automatically Generated Multi-Lattice Transitions’?

I have always been extremely fascinated by 3D printing technology and did a variety of 3D printed projects during my undergrad. Including designing modifications for computer cases, small adapters for home projects, and even a replica FANUC robot arm. When I came to graduate school, I really had no idea what I wanted to research, but I knew I had experience in additive manufacturing and I was interested in learning more about machine learning.

I was very excited to work on a project under the guidance of Chris McComb and Nick Meisel that would allow me to further research both!

They acknowledged that using discrete, functionally-graded lattice types only explores a portion of the huge design space that is possible with additive manufacturing.

The project aims to magnify the design space by using machine learning to develop transition regions between different types of lattices.

What is the ultimate goal of this research?

To understand how the strengths and weaknesses of machine learning for developing transition regions between different types of lattices.

The ability to use multiple types of lattices in a single structure opens up the design space for a variety of different applications.

Multi-lattice structures can expand on the benefits of functionally graded lattice structures, as they allow for more flexibility in the properties of the unit cells. Unfortunately, the design of multi-lattice structures is extremely complex, which is why machine learning is a natural choice for addressing it.

How did you select the specific unit cells for exploration in your study, and what software did you utilize to create and evaluate their behavior?

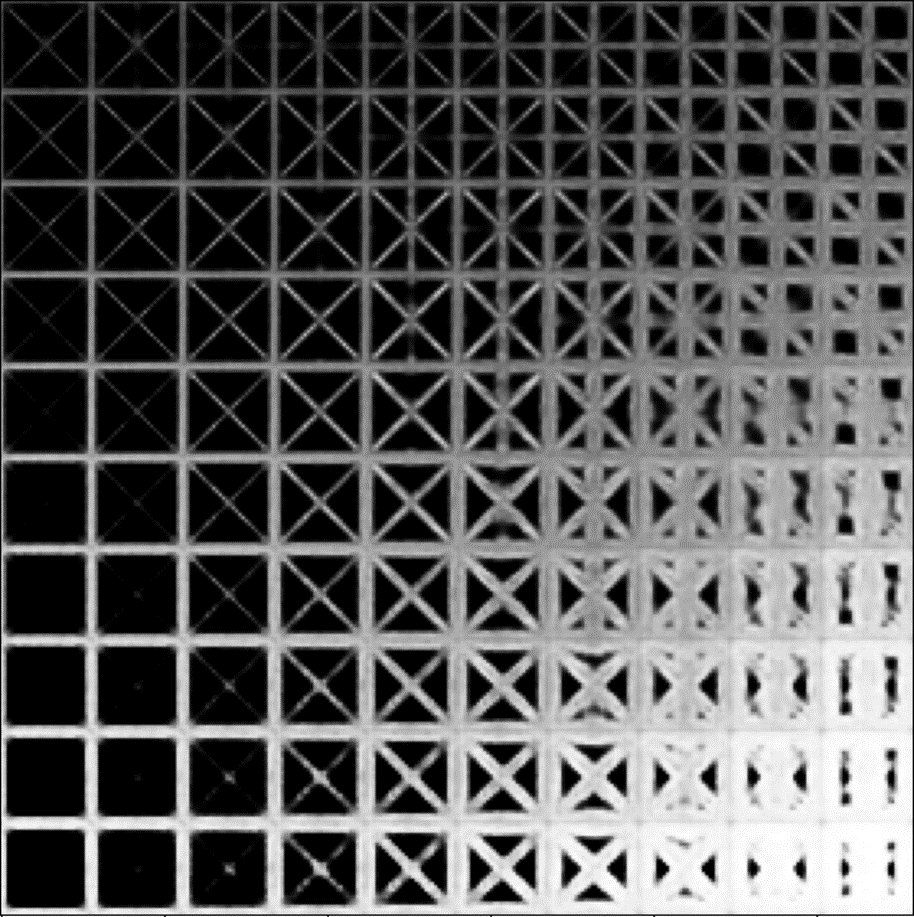

Originally, we developed a simple 2D strut-based dataset to determine the feasibility of our approach. The unit cells chosen were based on the lattices used in other additive manufacturing research that demonstrated them to be foundational building blocks and build a dataset of about 400 unit cells using Python.

Even with such a small dataset, we were able to analyze some of the relationships the data had with the latent space. To evaluate the transition regions, we started by designing a smoothness metric to measure the change between consecutive unit cells, in order to measure the performance of a transition region. This smoothness metric was designed to measure the flow between adjacent unit cells, where less directional changes in the flow meant that the unit cells were more similar to one another.

Future work will utilize a full factorial version of this dataset that contains over 700k datapoints, which was made using our strut-based development tool discussed in our paper “AddLat2D the 2D Lattice Generator”. This tool is available for public use on our Hugging Face!

Could you elaborate on how you used machine learning, specifically Variational Autoencoders, to automate the design of transitional areas between different lattice structures?

What makes Variational Autoencoders unique is their ability to generate new unit cells based on a reduced representation of the unit cells in the training data.

This allows the development of a huge number of intermittent unit cells to improve the smoothness of the transition region at a low computational cost.

The process of training the Variational Autoencoder involves two major components: 1) teaching the encoder to create a reduced representation of the unit cell, and 2) teaching the decoder to reconstruct the original unit cell from the reduced representation.

The combination of these reduced representations creates what is called a latent space, which is organized based on the model’s interpretation of similarity between each unit cell.

The transitional regions are then created by traveling in the latent space between two selected endpoint unit cells. Using this approach allows the transition length to be as many unit cells as desired, and provides the flexibility to choose amongst a wide set of unit cells.

How did you expect the latent space to affect smoothness of transition regions, and how does that compare to what you observed in the experiments?

I originally predicted two primary variables would affect the smoothness of the transition regions; distance in the latent space, and the length of the transition region, or the number of unit cells in a transition region.

We expected that increased distance in the latent space would mean that the unit cells were drastically different from one another, and would therefore result in worse transition regions. At the same time, we thought that increasing the number of unit cells in a transition region would help to mitigate the effects of distance, and improve the smoothness of a transition region.

We confirmed that 95% of the variability in smoothness can be described by transition length and distance alone.

Using our smoothness metric, we found that the distance between two unit cells in the latent space has the biggest impact on the smoothness of the transition region, while the number of unit cells in the transition region only had a small impact on its performance.

Ultimately, transition length alone has no impact, which means that distance in the latent space is the primary contributor to smoothness.

These realizations have influenced the progression of our current research into addressing the design of multi-lattice structures.

These first experiments are centered on 2D lattice structures. How do you plan to extend this research into 3D space, given that it will introduce at least one other dimension of complexity?

The initial results have proven very promising for creating the framework to work on 3D unit cells.

Since the model is entirely dependent on the dataset provided, the transition to 3D will require an extremely diverse 3D dataset. Additionally, it is desirable to have a dataset that is as close to full factorial as possible. Therefore, I expect that we will need to apply some data augmentation techniques to fully expand the dataset to improve the performance of our model. There will also be some architecture changes necessary to process the increase in dimensionality, which may involve changing the representation of the data to a form that is easier to process. Otherwise, the model will be extremely similar to our current model, as it is a form that is extendable to 3D. Preliminary testing using extruded versions of the strut dataset has proven that the model itself can be easily modified for 3D data processing.

In your paper, you've touched on the limitations concerning manufacturability and material properties, such as self-supporting angles and minimum feature size. How do you plan to address these complexities as you extend your research into 3D lattice structures?

The first step is to determine how to appropriately measure minimum feature size and self-supporting angles for our data.

A lot of inspiration for approaching this problem will start with researching industry-standard slicing approaches. The goal is to create a method that can be extended to multiple printing technologies. Once we can robustly identify structures that are not manufacturable, we can incorporate those restrictions into our interpolation method.

What commercial applications do you anticipate for your research on transitional lattice structures, particularly once you've successfully tackled the complexities of 3D lattices, as well as addressed issues related to materials and manufacturability?

The literature surrounding transitional lattice structures suggests that their behavior mimics that of functionally graded structures, and therefore have similar application areas.

I expect that multi-lattice structures will have more desirable characteristics and replace graded lattice structures in a variety of applications as design software enables engineers to take advantage of them.

The most promising applications include impact reduction, heat transfer, fluid flow, and likely many more.

Given the potential applications you foresee, are there specific sectors or companies you're interested in partnering with to further explore your research or bring findings into real-world applications?

I think the first step is to bring this technology to lattice design softwares, as they can make the design of products possible.

I am extremely interested in learning more about software development and how something like this would be properly incorporated into a usable product.

We are currently partnering with Metafold to develop our 3D dataset for our future research, and are more than happy to discuss further collaboration options with other lattice design companies.

In terms of companies looking to apply this research to product development, I would like to again reiterate that any application that is currently using the flexibility of functionally graded lattice structures should look into applying multi-lattice structures.

Companies that explore applications of impact reduction, heat transfer, and fluid flow would be a great place to start applying this research.

If you are interested in learning more about design, simulation and manufacture of lattice structures, Elissa Ross of Metafold, along with other leading software developers and engineers at the cutting edge of architected materials will be presenting at CDFAM Computational Design Symposium in Berlin May 7-8 2024.

Register now for two days of presentations and networking with the leaders in computational design, engineering and architecture.