Spherene vs. Gyroid

Conformal, Isotropic and Surface Normal

In an interview with Spherene founder and CEO Christian Waldvogel, we explore a novel type of minimal surface distinct from the traditional Triply Periodic Minimal Surfaces (TPMS) like Gyroids, widely utilized in Additive Manufacturing (AM).

Spherene Software: Metamaterial Design Tool

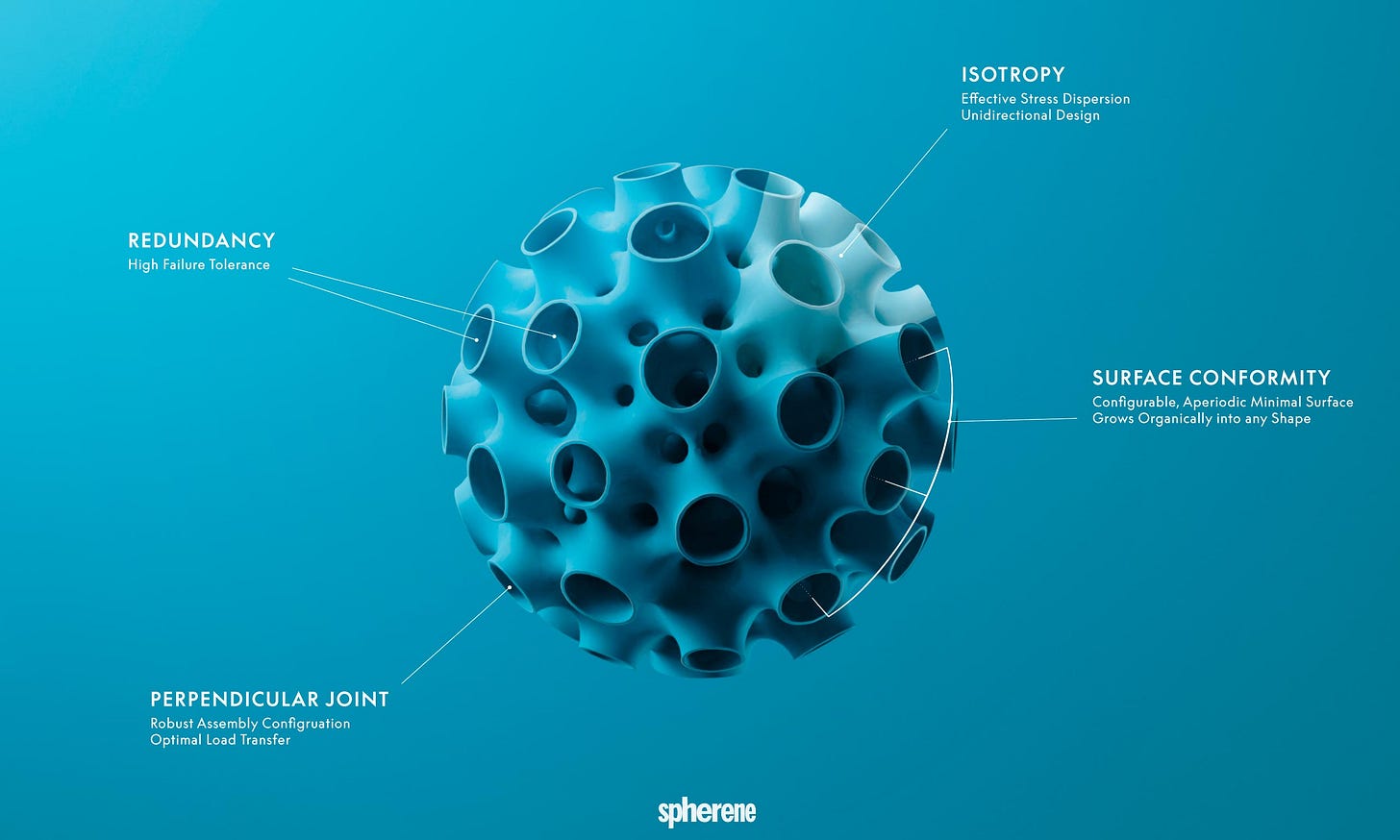

Spherene software emerges as a tool designed to generate 'Adaptive Density Minimal Surfaces' (ADMS) that adeptly respond to a part's requirements—ranging from functional demands and material properties to aesthetic considerations and manufacturing constraints.

Unlike “traditional TPMS” approaches that modify and repeat unit cells, Spherene software constructs minimal surfaces tailored to specific design contexts, ensuring optimal material placement and mechanical performance with minimal waste.

Spherene vs. Gyroid: Technical and Practical Distinctions

While both Spherene and Gyroid structures belong to the minimal surface family, characterized by zero mean curvature, their similarities end there.

Spherene structures are crafted from the outside in, allowing the entire part's geometry, including complex features like openings and interfaces, to be seamlessly integrated without the need for additional structural adjustments.

This method contrasts with the Gyroid (and other TPMS) approach, where repetitive unit cells often require modification to fit non-standard shapes, leading to potential structural inefficiencies and floating geometries.

Applications and Future Horizons at CDFAM

At the upcoming CDFAM Symposium in Berlin, the practical applications of Spherene will be showcased through various demonstrations, including an ESA satellite bracket and biomedical implants, underscoring its versatility of performance in diverse settings.

These examples not only demonstrate Spherene's capacity to tailor material properties and enhance product functionality but also highlight its potential to significantly impact design efficiency and sustainability in manufacturing.

Integration and Workflow Compatibility

Spherene's integration with existing design and engineering ecosystems is facilitated through a cloud-based API, ensuring compatibility and ease of use across different platforms and workflows. With the first iteration available in Rhino’s Grasshopper, considered the backbone of computational design practice in many fields making it easily accessible and integrated into existing design and engineering workflows.

Learn More

Read the full interview to learn more about Spherene software and register to attend CDFAM Berlin to connect with Christian and other experts in computational geometry and engineering.