Where Machine Intelligence in Computational Design Does and Does not Work.

Interview with Gabrielis Cerniauskas, The University of Edinburgh

Can you start by giving us an overview of your work at the University of Edinburgh and the types of projects you’re involved in?

I’m involved in a couple of really exciting projects where I get to blend cutting-edge technology with smart engineering solutions.

One part of my work focuses on designing materials — called metamaterials — that have unusual properties such as bending electromagnetic waves or absorbing vibrations. We’re really pushing the boundaries by using simulations and experiments to make sure these metamaterials can do what we envision.

I’m also looking into big lattice structures that could revolutionize the way we build infrastructure for renewable energy, like wind turbines. These structures are all about using less material while maintaining strength, so they’re lighter and cost-effective but still tough enough to handle high fatigue loads.

Another cool aspect of my job is using machine learning to figure out the residual material strength after it’s been damaged. Particularly, I look at fibre-reinforced polymer composites, which are commonly used for automotive and aerospace applications. By predicting how these composites behave after taking a hit, we can make them safer and more reliable.

All in all, my work is about making materials smarter and structures more sustainable, which, I believe, is not only fascinating but also super important for future development.

Your presentation at CDFAM NYC focuses on the use of machine intelligence in computational design. Could you explain how AI and ML are being integrated into the design process and what distinguishes these methods from traditional optimization techniques?

In my view, AI and ML techniques are simply the next progression, the next iteration from traditional computational design methods. They might not serve the exact same purpose and their strengths might be different from traditional optimisation techniques but they do have some niche applications in computational design.

The key difference to remember here is that AI and ML tools are not built on hard logic or direct analysis but are rather providing us a quick “good enough” solutions to the given problem.

There are a few examples of how these tools can be integrated into our design processes which, I will cover in my talk, but they mostly focus on making the design process either quicker, by sacrificing a small portion of the output accuracy, or by enabling us to solve new design and engineering problems that would otherwise be too complex or too time-consuming to solve using traditional methods.

What are the key benefits of applying AI and ML to the design and discovery of lattice structures and other cellular solids?

AI is nothing without data. This is unfortunately a major obstacle when implementing AI/ML tools for design purposes where we lack extensive prior designs to train our models.

Hence, if you start from scratch it’s easier to use direct solvers and hard logic-based algorithms. However, if you have data, then go ahead and explore everything AI/ML has to offer. You can then train a model which will provide you with a solutions that has around 80-90% accuracy in seconds rather than 95+% in many hours using traditional methods.

In your talk, you plan to critique where AI and ML are effective and where they fall short. Could you share some examples of both successful and less effective applications?

Yes, AI is not a silver bullet and just because the term “AI” has become a buzzword in the last few years, it does not mean physics-based methods will become obsolete.

AI is not always accurate and it is easy to spot when this is the case. Large language models are good at writing essays if they are not too technical but it’s very obvious that they make mistakes when you ask them to solve mathematical equations.

Similar trends can be seen for ML-powered models that are designed to predict rather than solve to get an answer. Hence, you would never use AI, for example, to solve partial differential equations or as a substitute tool to replace finite element modelling.

As for successful applications, AI, in my opinion, should be used for “softer” computational design tasks that do not necessarily rely on strict logic or math. A couple of examples could be designing Voronoi structures or suggesting the most suitable lattice arrangements based on previous training data.

Register to attend CDFAM in NYC, October 2-3, 2024 to connect with experts in computational design and engineering at all scales.

How do you categorize different machine intelligence approaches in computational design, and what trends are you observing in this area?

What a coincidence, I actually have a review paper looking exactly into this.

To be honest, it is quite difficult to categorize machine intelligence approaches and there is no consensus just because it is such a quickly evolving field at the moment and people are discovering new ways of using different AI/ML approaches every day.

From a metamaterial and lattice structure design perspective, I think there are three or four main categories which are simple machine learning algorithms, such as linear or polynomial regression, decision trees, etc., nature-inspired algorithms, best known are probably genetic or particle swarm approaches and artificial neural network (ANN) based approaches. The last category would be the large language models (LLMs), they are actually built using large ANNs, and are just emerging as a way to optimise and generate new structures. As I said, new applications are being found every day.

You’ve worked on projects involving the use of large-scale lattice structures in industrial applications, such as weight reduction in wind turbines. Have AI and ML models helped contribute to solving practical engineering challenges in these projects?

Yes, absolutely. In this specific case, we were designing a lattice structure that has different arrangements depending on the section’s position within the blade. This is due to the wind turbine blade experiencing varying flapwise and edgewise loads in each section. As you might expect, wind turbine blades are massive, with the largest ones currently exceeding 120 meters in length.

The ML-powered framework, that we built for this project, allowed us to do a quick prediction of an optimal lattice structure for each section significantly reducing our computational time. A simple exploratory optimisation task of this size would have taken us more than a few months to complete using basic search algorithms.

What key insights or lessons do you hope the audience will take away from your presentation?

– Don’t believe that AI will solve all your problems. Like every new tool introduced to the market, there are niche applications that demonstrate its benefits. The overall hype about AI is tainting its reputation and creating sceptics, whereas we should see where it actually works

– I believe AI will eventually be the most beneficial for design automation and will help us reduce the time needed to generate new designs by reducing computation time.

Finally, You have been to every CDFAM event so far (thanks for your support), what do you hope to gain from attending the next one in NYC?

It has been my absolute pleasure to attend the CDFAM events where I get a chance to share and learn the latest advances in the field of computational design that take place around the globe.

I enjoy seeing how this new field is growing in numbers while changing and progressing at the same time. As for what I hope to gain, I’m certain I will have a great deal of fun.ecisions that align with both performance goals and sustainability targets.

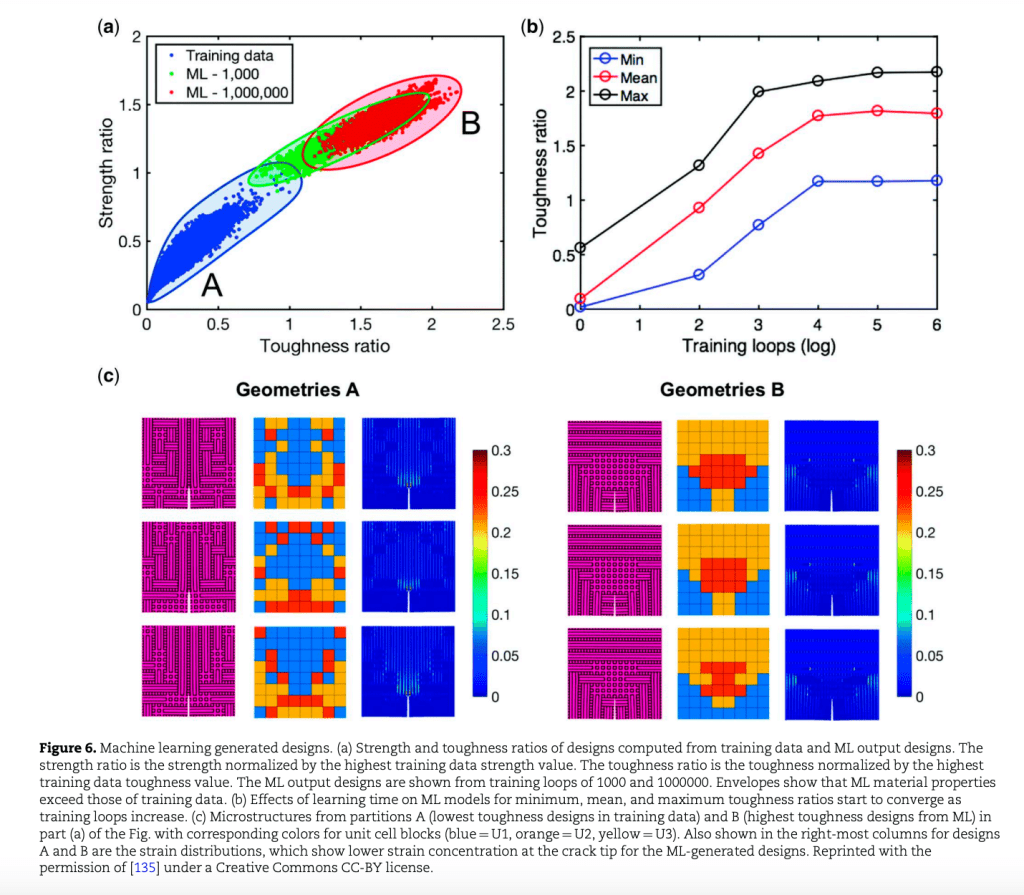

Images via Machine intelligence in metamaterials design: a review

February 2024, Oxford Open Materials Science 4(1)