Organization

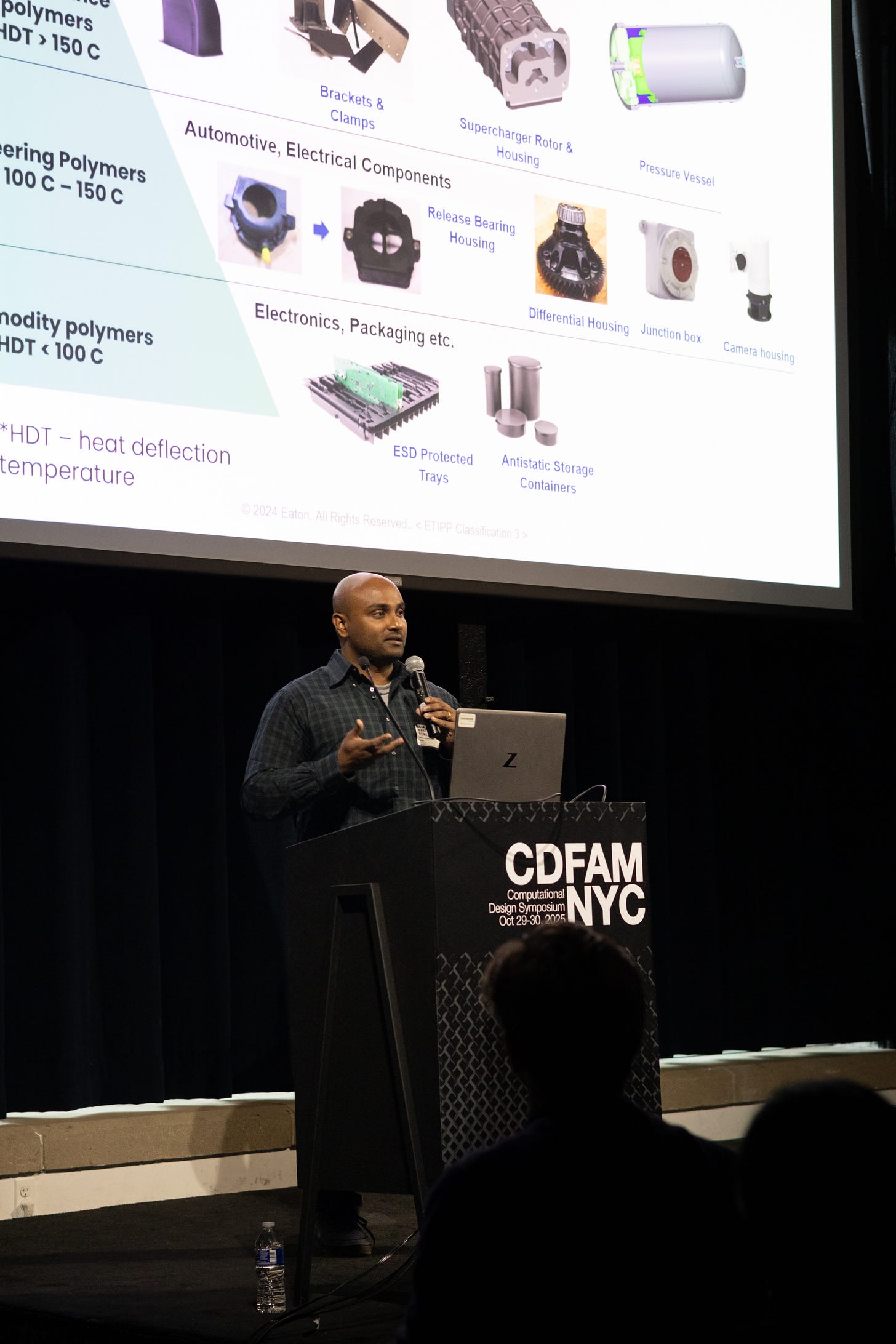

Eaton + Intact Solutions

Presenter:

Karthik Rajan Venkatesan

Neel Kumar

Accelerating Metal-to-Plastic Conversion with AI, Implicit CAD, and Mesh-Free Simulation

Presentation Abstract

This work presents a simulation-driven generative design framework for reengineering a metallic explosion-proof enclosure into a lightweight, injection-molded fiber-reinforced plastic alternative. The methodology integrates advanced process and performance simulations with AI-guided optimization to enable rapid, intelligent design iteration.

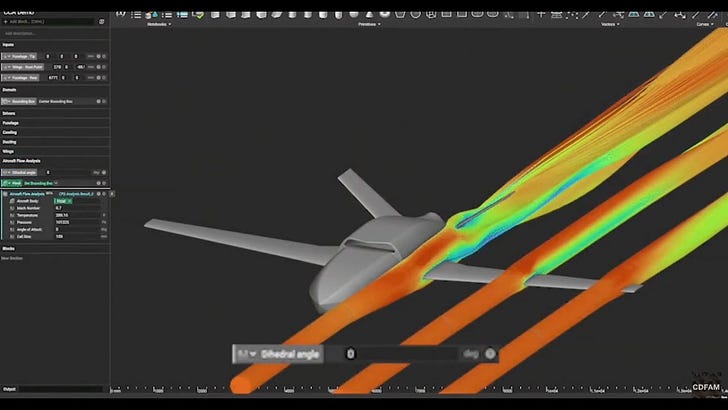

Central to this workflow is the use of implicit CAD modeling in nTop, which allows for highly flexible and parameterized geometry generation, seamlessly integrated with a robust, mesh-free simulation engine from Intact Solutions. This combination eliminates traditional meshing bottlenecks and enables direct evaluation of complex geometries without meshing or format conversion.

The workflow is executed in two stages. Stage I establishes baseline using Moldflow for plastic flow simulation, Digimat for fiber orientation mapping, and ABAQUS for traditional FEA, culminating in a stress field point cloud. Stage II transitions to an AI-driven design space exploration loop, where models are trained and evaluated through a Bayesian optimization framework. The implicit CAD models are directly analyzed using Intact.Simulation for Automation without any manual pre-processing, enabling a seamless feedback loop between design and performance while supporting rapid, large-scale design iterations.

This approach exemplifies the power of computational design at scale—reducing turnaround time from over 48 hours with traditional CAD and FEA methods to under 1.5 hours with the full AI-driven pipeline with implicit modeling and automated, mesh-free simulation.

Speaker Bio

Karthik Venkatesan is a Lead Engineer in Computational and Digital Product Development at Eaton’s Center for Materials & Manufacturing Innovation in Southfield, Michigan. His work focuses on bridging advanced simulation, AI, and generative design to accelerate the development of next-generation engineered systems. Karthik leads R&D initiatives that span simulation-driven design automation, lightweighting, and digital workflows for both traditional and additive manufacturing (AM) processes.

He holds a Ph.D. in Mechanical Engineering from Arizona State University, where he led multiscale modeling efforts for composite materials under DoD- and industry-funded programs. His broader research spans geometry compensation for binder jet AM, performance prediction for polymer extrusion-based AM, virtual design of experiments, and generative AI for material discovery.

Karthik is also passionate about computational creativity, with interests spanning astro photography, AI-generated media, and music production