Recorded at CDFAM Computational Design Symposium, NYC 2024

Presentation Abstract

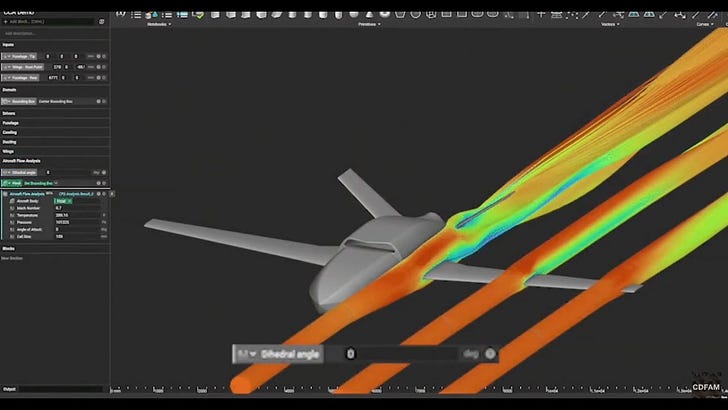

Additive manufacturing (AM) technology has afforded greater degree of geometrical design freedoms not otherwise available through traditional manufacturing. Multi-material laser powder bed fusion (MM-LPBF) combines the great geometric and surface roughness resolution associated with LPBF with selective powder deposition (SPD), allowing for the special tailoring of material based on functional design requirements. For instance, advanced heat exchanger design can now include copper fins for efficient heat dissipation combined with nickel alloys for structural strength, and stainless steel for corrosion resistance. The ability to selectively engineer the design and material assignment of multiple metals in true 3D voxel approach into a single component can produce extreme design advantages for both part consolidation and unnecessary material reduction. In most engineering applications (e.g. aerospace, automotive, space) weight is considered a critical design factor. Part and assembly consolidation, as well as light weighting associated with new AM technology, can now be extended beyond traditional single material design and on many length scales. To facilitate this aspiration, we have developed a framework utilizing topology optimization capable of simultaneous multi-material design, inspired by the newfound design freedoms enabled by MM-LPBF. Our motivation exists to investigate and develop new design methods which incorporate manufacturing process considerations (e.g. build orientation, minimum feature size) to produce multi-material metallic designs which meet clear objective functions, such as maximizing stiffness or thermally fluidic heat dissipation.

Speaker Bio

Dr. Guha Manogharan is the Emmert H. Bashore Faculty Development Associate Professor of Mechanical Engineering at The Pennsylvania State University – University Park. He is the Co-Director of CIMP-3D (Center for Innovative Materials Processing through Direct Digital Deposition (CIMP-3D) and also heads the Systems for Hybrid – Additive Processing Engineering – The SHAPE Lab which focuses on additive and hybrid manufacturing with an emphasis on biomedical, defense and aerospace applications. Dr. Manogharan received his Ph.D. (2014) and M.S. (2009) from North Carolina State University. He has received the 2022 ASME Early Career Leadership (ECLIPSE) award, and several young investigator awards (2021 ASTM, 2020 NSF CAREER, 2018 FAME Jr., 2017 SME Outstanding Young Manufacturing Engineer Award and 2016 IISE Outstanding Young Investigator by Manufacturing and Design Division). His current work is supported by NSF, DoE, ONR, AFRL, IACMI, and Manufacturing PA.

CDFAM Computational Design Symposium series brings together leading experts in computational design from industry, academia and software development for two days of knowledge sharing and networking.

Visit CDFAM.COM to learn about upcoming events around the world.